Audi grandsphere concept

First class toward the future

The private jet for the road – At the IAA 2021, Audi is presenting the Audi grandsphere concept study. Like a first class flight, the 5.35 m (17.6 ft.) long grandsphere sedan combines the luxury of private travel in the greatest of comfort with a comprehensive onboard experience offering.

Level 4 automated driving makes new dimensions of freedom possible: in this mode, the interior turns into a spacious sphere of experience without a steering wheel, pedals, or displays. And the front seats become a first class lounge with maximum space, freer views, and access to all the functions of a holistic digital ecosystem that the Audi grandsphere is integrated into.

As the second of three “sphere” concept cars from the brand with the four rings, the Audi grandsphere has a special place. That is because the technologies and design features assembled in it will turn up again within a few years in future Audi series. The Audi grandsphere concept illustrates the brand’s claim that it is becoming the trendsetter at the top of the automotive industry for technological transformation and completely new, holistic mobility offerings.

The electrically driven roadster Audi skysphere concept debuted in August 2021 – it was a spectacular vision of an automatically driving GT that transforms into a self-driving sports car with a variable wheelbase. These two concept cars – as well as the Audi urbansphere, which will appear as the third part of the trio in 2022 – are linked by their overall concept, which is derived from their ability to drive automatically at level 4. Audi is working with CARIAD, the Volkswagen Group’s software think tank, toward introducing that technology in the second half of the decade.

Level 4: not only does it change the interior space of the traditional driver-oriented cockpit and passenger seats into a spacious lounge as soon as the steering wheel and pedals are reduced. At the same time, it opens up new levels of freedom for all the passengers. That is because the Audi grandsphere not only frees the driver from the tasks of driving whenever possible, but at the same time also offers everyone onboard a wide range of options to use that freedom for individually variable experiences: communication or relaxation, work or withdrawal into a private sphere as desired. The Audi grandsphere concept transforms from being strictly an automobile in an “experience device.“

Thanks to Audi’s own services and the ability to integrate digital services, the possibilities are nearly endless. These can be used to access a variety of service options related to the current trip – such as designing a spectacular scenic route, as well as restaurant or hotel options. The vehicle also takes care of everyday tasks that go beyond the ride itself. For example, the autonomous Audi grandsphere concept picks up its passengers with information about their current destination and independently handles parking and charging.

Customized infotainment options are also available, such as seamless integration of onboard streaming from music and video providers that have been used previously. In an additional step, Audi will keep personalized and exclusive options available in the future – concerts, cultural events, or even sporting events that customers are invited to.

The Audi grandsphere concept illustrates the brand’s claim that it defines the progressive luxury of the future: for Audi, that includes the option of new high-class experiences, enabled by digitalization, as well as a holistic approach to sustainability with the goal of carbon neutrality in the near future along the entire value chain.

First class for the future times three

Audi skysphere, Audi grandsphere, and Audi urbansphere are the three concept cars that the brand with the four rings is using to showcase its vision of progressive luxury. In the process, Audi is creating a vehicle experience that goes far beyond the purpose of merely spending time in a car to get from point A to point B, and even far beyond the driving experience itself.

These concept cars feature a new design that ultimately reimagines the interior, the passenger compartment, as the center of the vehicle and no longer subordinates the passenger experience to the requirements of the technology. This is reflected in the variable layout of the interior, the disappearance of the controls, and the sheer expanse of the cabin, in addition to linking them to new service offerings.

The design process – from the inside out

Even the “sphere” in the name sends a signal: the heart of the Audi skysphere, grandsphere, and urbansphere concept vehicles is always the interior. The drive system and the handling are no longer at the top of the design specifications in this new generation of cars. Instead, the starting point is the interior, the occupants’ living and experience sphere while traveling. Their needs and desires shape the space, the architecture, and the functions. With that reassessment, the design process itself changes. At the beginning of all discussions, the focus is directed toward the interior and its design. Only after that do we design the package, exterior lines, and proportions that shape the car into a total work of art, along with the technological premises.

Space, form, function – the interior

The doors of the Audi grandsphere concept are reversed so front and back touch; there is no B-pillar. The whole world of the interior opens up to passengers as soon as they climb in. But even before that, the Audi grandsphere has identified its passengers with a pathway identification – an innovative feature – that opens the doors and welcomes them with individually staged displays and ambient light. The driver and passenger positions are automatically detected and an array of personal comfort features – such as the climate control settings and the seats – are adjusted for the individual seats. At the same time, the infotainment system accesses the passengers’ most recently used services and seamlessly resumes them inside the car. For instance, a video that a passenger was streaming on a tablet is automatically played back over the display surface in the Audi grandsphere. On the driver’s side, on the other hand, the projection surface automatically picks up on displaying the news the occupant was reading before getting in.

In the interior, the lines on the decorative surfaces and functional elements are emphatically horizontal. The open, broad interior supports the impression of a unique space and the lack of a steering wheel, pedals, or conventional dashboard create a feeling of openness and breadth.

The large glass surfaces, expansive windshield, and transparent ceiling also emphasize that feeling. The same goes for the particular geometry of the side windows: their upper half is distinctively angled – the widest part is just slightly above eye level. It is a trick that Audi demonstrated for the first time in 2017 with its futuristic AI:CON concept car and which is now moving toward series production.

The change in the comfort zone is radical: if the boss’ seat is in the back in a conventional sedan, first class has now shifted forward into the front row. That is because it is no longer necessarily subordinated, first and foremost, to the driving function and the controls. In level 4 driving, the steering wheel and pedals disappear and the front area of the cabin becomes actual free space in all its breadth, with a perfect view through the large front and side windows, as well as maximum possibilities for movement.

The interior appears particularly wide when the two individual front seats are pushed all the way back. The Audi grandsphere is a 2+2-seater. An upholstered, two-person bench with an armrest that goes around the side is integrated as a seating option in the back, while both front seats are designed for first class comfort and space.

The seating surfaces and backs of the two seats with integrated belts are visually separate. The side bolsters of the seat backs are discreetly bent, thereby ensuring support while driving through curves. The possible seat positions are optimized for every use: in the upright position, the Audi grandsphere can be perfectly ergonomically controlled – as desired and outside level 4 zones. With the back tilted 40 degrees, passengers can relax and use the infotainment system. Finally, if the back is folded out to 60 degrees, it achieves a perfect resting position. The headrest can be bent 15 degrees forward. Outlets for air that is filtered and temperature controlled – even scented, as desired – as well as speakers that are inaudible to other passengers and allow for a private aural zone are all integrated into this area.

Between the front seats – normally concealed under metallic trim – there is a compact, onboard cooler with two glasses and a designed, elegant bottle for soft drinks. This is another sign of the Audi grandsphere concept’s first class claim.

No fittings, no screens: displays and operation

One surprise when looking around in the Audi grandsphere’s natural-colored, reduced-design interior: neither batteries of dial instruments nor black screens for virtual display concepts are visible before activating the driving functions – the oft-cited digital detox at its finest.

Instead, there are clearly articulated and sedate areas with materials of the highest quality. Wood and wool, synthetic textile fabrics and metal are visible and pleasant to touch as wall cladding, seat covering, and carpeting. Many of these materials, like the hornbeam veneers, come from sustainable cultivation or are made from recycled raw materials. There is no leather in the Audi grandsphere – even this is in keeping with a progressive understanding of luxury, which is always inseparable from sustainability.

Another surprise whenever the vehicle comes to life at the touch of a fingertip: there are displays – but they take the form of projections on the wooden surfaces under the windshield. Depending on the driving status – whether manual with a steering wheel or level 4 – they are either distributed across the entire width of the interior or segmented for the driver and front seat passenger. All the information that is necessary while traveling is there in high resolution and precisely readable.

Alternatively, the projection surfaces can also be used – in automated driving mode – as CinemaScope screens for infotainment content or even as screens for video conferences. In addition, a sensor bar is integrated under the projection surfaces for quick switching between content – for instance, for music or navigation. It shows all the functions and applications that are active in the car. Icons flash for the different menus.

One particular, extremely innovative control element is located near the door cut-out on the interior cladding: the MMI touchless response. If the driver is sitting in the active position behind the steering wheel, far toward the front in the interior, he or she can use that control to haptically select various function menus via a rotary ring and buttons and click through the different levels. A simple, intuitive operation.

If, on the other hand, the driver reclines the seat far to the back during level 4 driving, he or she does not have to do without these comfort items. That is because, at that point, a combination of eye tracking and gesture control are used. A sensor directed at the eye detects the line of sight when the control unit is to be engaged. And the passenger only needs to make analogous hand motions – without leaning over – that are similar to haptic operation and can use the system just as well that way – without touching a thing.

Whether it is eye tracking, gesture or voice control, handwritten input, or touch, the same thing applies to all operation modes: the Audi grandsphere concept adjusts to the individual user and learns his or her preferences and frequently used menus – and on that basis it can not only sensibly complete rudimentary commands, but also give personal proposals directly to the user.

Control panels are even integrated into the armrests on the doors. That way, the car always offers passengers invisible touch surfaces using an optic indicator to show its position. At the same time, there are VR glasses in the armrests on the left and right doors that can be used in conjunction with infotainment options – for instance for the holoride system.

Dynamic monolith – the exterior design

At 5.35 m (17.6 ft.) long, 2 m (6.6 ft.) wide, and 1.39 m (4.6 ft.) high, the Audi grandsphere concept’s measurements reveal this sedan as an unambiguous example of the luxury class automobile. The 3.19 m (10.5 ft.) wheelbase indicates top value, which even overshadows the long version of the current Audi A8. But even more striking than what these figures suggest is the visual impression that it makes upon seeing it for the first time. That is because the Audi grandsphere looks nothing like a traditional sedan, but rather more like a tightly drawn four-door GT with a line the comes straight from the wind tunnel. And it does that while doing without any decor or superfluous flourishes.

In the process, the Audi grandsphere consistently implements the specific conditions of the electric drive system right in the front end – a short overhang, a flat hood, and the windshield that projects far forward as the foremost limit of the large interior. Nonetheless, unlike many electric cars, it does not look futuristic at all, but rather emphasizes traditional beauty ideals. The top edge of the hood is drawn far into the side of the chassis in a horizontal line, suggesting a long engine compartment – all characteristics of a GT. In the rear, that line continues at the same height across the rear wheel well, encompassing the whole cabin and emphasizing its size.

A second horizontal line emanates from the bottom edge of the hood and runs under the side windows and likewise around the entire cabin. This subdivides the door surfaces into horizontally oriented shoulders and the convex verticals below them above the rocker panel. The wheel wells have a soft, yet distinctive shape – typical Audi. The slender rear behind the massive C-pillar is a quote from traditional streamlining. And the dynamically sloping arc of the roofline reveals the grandsphere as part of the Audi Sportback tradition. All lines and all surfaces seem to organically correlate, combining to form one monolithic body.

At 23 inches, the wheels of the Audi grandsphere concept quote an icon from the 1990s – the Audi Avus. At the same time, the six double spokes signal light construction and stability, recalling functional motorsport wheels and the Bauhaus tradition in brand design.

Visible technology – light

In the front end, there is an innovative interpretation of the Singleframe that defines Audi’s look: it is shaped like a flat hexagon. The interior surfaces, behind a transparent covering, are indirectly lit from above while driving – a distinctive, extremely three-dimensionally structured visual effect.

The headlight units on the upper side of the Singleframe look narrow, like focused eyes. The lighting units reference the four rings brand logo: they enlarge and isolate the intersection of two rings into a pupil – a new, unmistakable digital light signature. This means that the size of the light areas can be adjusted according to their function as daytime running lights or as dynamically staged blinkers – depending on the traffic situation – and thereby issue an obvious signal in the interest of safety. The same graphic is also in the rear lighting units – another significant characteristic of the Audi light design.

Drive system and charging

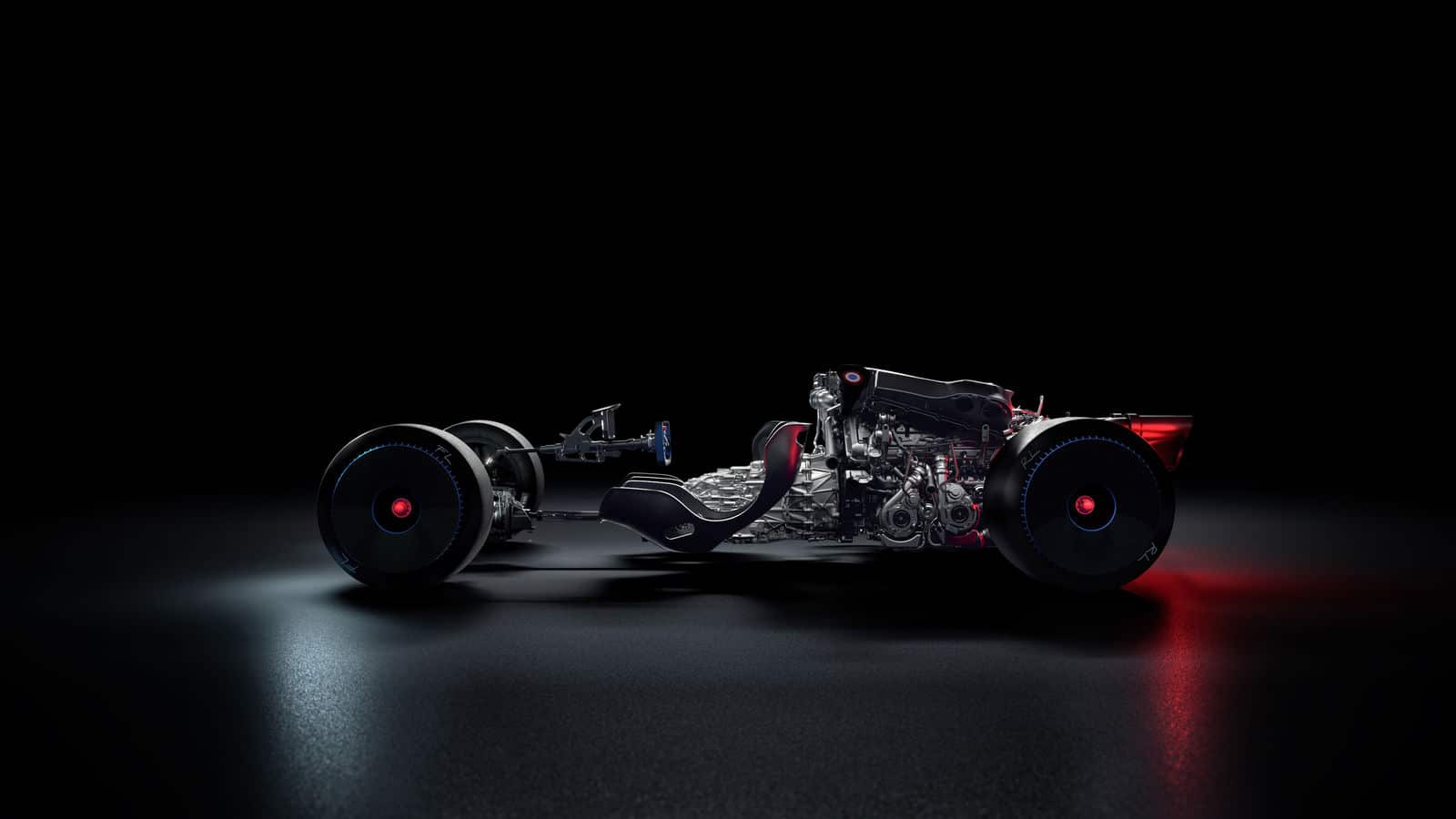

The technology platform of the Audi grandsphere – what is known as the Premium Platform Electric, or PPE – was conceived exclusively for battery-powered electric drive systems and therefore it takes full advantage of that technology. The key element of PPE is a battery module between the axles that holds around 120 kWh of energy in the grandsphere concept. A flat battery layout is possible because Audi uses the entire vehicle base between the axes.

Together with the large wheels, this produces basic proportions that are perfect not only from a design perspective. The core benefits include a long interior and therefore legroom in both rows of seats. Additionally, the absence of a gearbox cover and a cardan tunnel increases spatial comfort in electric cars.

Nonetheless, the Audi grandsphere does not forego the quattro drive system, which is essential to the brand. That is because the concept car has separate electric motors mounted on the front and rear axles that use electronic coordination to deliver all-wheel drive on demand and execute a perfect balance between driving dynamics and energy efficiency. The Audi grandsphere concept’s two electric motors are capable of delivering a total output of 530 kW and a torque of 960 Newton meters.

Fast charging, high range

The heart of the drive system is the 800 volt charging technology. Like the Audi e-tron GT before it, this technology ensures that the battery can be charged with up to 270 kW in a very short time at fast-charging stations.

This strategy makes charging times that approach a refueling stop for a car with a conventional engine possible. Just ten minutes are enough to charge the battery to a level sufficient to power the car more than 300 kilometers (186 miles). In less than 25 minutes, you can charge the 120 kWh battery from 5 to 80 percent.

Together with a range of more than 750 kilometers (466 miles) – depending on the selected drive system and power output – the Audi grandsphere concept is unconditionally suitable for long distances. Furthermore, its range and charging speed keep pace with those of combustion engines, making it the perfect universal car for everyday needs.

In terms of dynamic qualities, the Audi grandsphere concept – as is typical for an electric car – truly outshines its rivals with combustion engines. Thanks to the high torque that is available from the first revolution, acceleration from 0-100 km/h (62 mph) takes just over four seconds; maximum speed is limited in the interest of increased range.

Air suspension and active suspension for maximum comfort

The front wheels are connected via a five-link axle, specially optimized for electric vehicles. In the rear, there is a multi-link axle that, like the front, is made of aluminum. Despite the long wheelbase, the steerable rear wheels provide excellent maneuverability. The luxurious Audi grandsphere concept touring sedan utilizes Audi air suspension – a single chamber system with adaptive dampers. Quite well suited for dynamic driving when necessary it guarantees gentle comfort without noticeable vehicle body movements, under normal conditions.

The reason: the Audi grandsphere concept has active suspension. The high-tech system can separately pull up or push down on each wheel separately in milliseconds via electromechanical actuators. That makes it possible to actively control the state of the chassis in every driving situation and therefore significantly reduce pitching and plunging when accelerating or braking. Thanks to the front camera, which recognizes unevenness, the adjustments happen predictively. The navigation system’s topographical data are also used to integrate curve radii, gradients, and inclines into the system’s projection.