Audi skysphere concept (2021)

Audi has unveiled the first member of a new family of concept vehicles, a spectacular roadster. Audi skysphere concept is the name of the electric-powered, two-door convertible whose lines lead directly to the Audi design of tomorrow. With it, the brand is illustrating its vision for the progressive luxury segment of the future, in which the interior becomes an interactive space and the vehicle a platform for captivating experiences. This is being made possible thanks to autonomous driving, a revolutionary redesign of the interior, and a seamless digital ecosystem.

The Audi skysphere concept shows how the brand is redefining luxury in the future – it’s no longer just about driving. The concept car was designed with the clear objective of offering its occupants captivating and world-class experiences.

Static photo,

Colour: Stage Light

To give passengers the maximum amount of freedom, the Audi skysphere concept was designed for two different driving experiences: a grand touring experience and a sports experience. This makes use of a spectacular technical detail – the variable wheelbase. Electric motors and a sophisticated mechanism with body and frame components that slide into one another make it possible to vary the wheelbase itself and the exterior length of the car by 250 millimeters. At the same time, the vehicle’s ground clearance is adjusted by 10 millimeters to enhance comfort and driving dynamics.

With the touch of button, the driver can take advantage of their freedom and choose their own driving experience– either they pilot their 4.94-meter-long e-roadster themselves in “Sports” mode with a reduced wheelbase, while the rear-wheel steering ensures that the vehicle remains extremely agile despite its dimensions. Or they can choose to be chauffeured around in a 5.19-meter GT in the autonomous “Grand Touring” driving mode while enjoying the sky and the scenery, maximum legroom, and the services offered by a seamlessly integrated digital ecosystem.

In this mode, the steering wheel and pedals move into an invisible area; the feeling of space in the concept car opens up completely new realms of possibility for such a sporty convertible. Meanwhile, the Audi skysphere automatically keeps an eye on the road and traffic with its sensor system and drives the occupants safely to their destination.

Static photo,

Colour: Stage Light

Similar to how the interior design offers a new, contemporary interpretation of luxury, digitization and the ecosystem open up unprecedented levels of freedom and worlds of experience for the vehicle’s passengers. Thanks to Audi’s own services and the ability to integrate digital services, the possibilities are nearly endless. In addition, the passengers can share their experience on the road with friends via social media, with images of the interior and the surrounding area. The vehicle also takes care of everyday tasks that go beyond the ride itself. For example, the autonomous Audi skysphere concept picks up its passengers with information about their current destination and independently handles parking and charging.

Static photo,

Colour: Stage Light

Audi skysphere to be unveiled on its home turf in California

The Audi skysphere concept will make its public debut on August 13, 2021, as part of Monterey Car Week – on the legendary fairways of the Pebble Beach golf course. This means the vehicle’s unveiling in California is taking place more or less on its home turf. This is because the concept car was conceived and designed at the Audi Design Studio in Malibu, just a stone’s throw away from the Pacific Coast Highway, the legendary coastal road that connects the suburbs of Los Angeles with northern California. Studio manager Gael Buzyn and his team are the creative minds behind the project. A legendary classic model from the company’s own history – the Horch 853 roadster – served as the inspiration for the new groundbreaking model. The impressive convertible, which is also around 5.20 meters in length, was not only the definition of modern luxury in the 1930s, but also won the Concours d’Elegance in Pebble Beach in 2009.

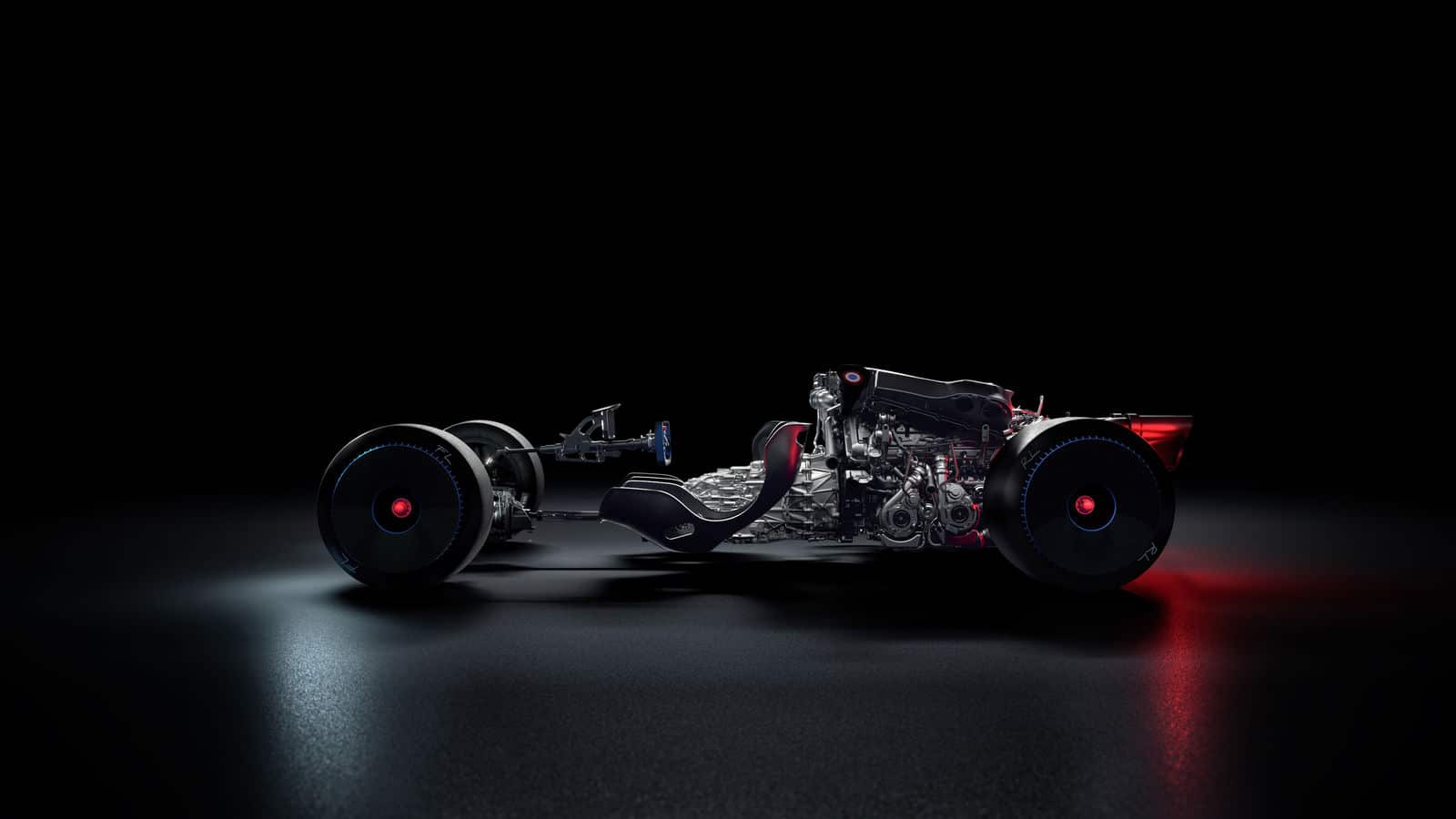

But the visual inspiration from its predecessor is limited to the concept car’s dimensions and typical proportions with a rather compact cabin and long front end. A look under the hood of the Horch reveals an imposing straight-eight engine with a displacement of 5 liters. The Audi skysphere, on the other hand, mainly has electric drive components between the front axle and the windshield, such as the charger and the DC/DC converter, plus the actuators and electronic and mechanical components for the adaptive wheelbase. It also features a spacious trunk filled with two golf bags specially designed for the concept car.

Static photo,

Colour: Stage Light

The drive system: 465 kW of power

“New technologies like electrification, digitalization, and autonomous driving gave us the opportunity to create an experience that goes way beyond the one that typical roadsters offer today,” said design project manager Gael Buzyn.

An electric motor positioned on the powered rear axle is responsible for delivering power to the wheels of the Audi skysphere. A total of 465 kilowatts of power and 750 Newton meters of torque have an easy time with the roadster, which only weighs around 1,800 kilograms. The weight distribution of around 60 percent on the powered rear axle results in ample traction and acceleration from 0 to 100 km/h in just four seconds, if required.

The Audi skysphere’s battery modules are primarily positioned behind the cabin – an ideal configuration for the vehicle’s center of gravity and agility. Further modules can be found between the seats in the center tunnel of the skysphere interior – another position chosen in favor of vehicle dynamics. The battery’s capacity is expected to be more than 80 kWh, giving the car a range of more than 500 kilometers according to the WLTP standard, at least in the economical GT mode.

Static photo,

Colour: Stage Light

The chassis: rear-wheel steering and adaptive air suspension

The vehicle features double wishbone axles in the front and the rear. The upper and lower wishbones are forged or cast from aluminum. Steering takes place via a steer-by-wire system that controls both the front and the rear wheels. Because the system is not mechanically connected to the front axle, the driver can select different steering ratios and steering settings – all at the touch of a button. This allows the steering to be adjusted from extremely direct to comfortable, but also from high self-aligning forces to minimal self-aligning forces, for example when parking. The rear-axle steering and adaptive wheelbase also contribute to the car’s small turning radius.

A long-established Audi chassis technology ensures that the suspension delivers the necessary level of versatility – the latest evolutionary stage of Audi’s adaptive air suspension has been implemented in the concept car and features three independent air chambers to provide a comfortable base suspension. Individual chambers can be deactivated for a more sporty ride with fast acceleration. The result is that the characteristic curve of the spring becomes more progressive, reducing roll and pitch to a minimum. Lowering the body by 10 mm reduces aerodynamic drag – particularly relevant when driving long distances.

The Audi skysphere’s active suspension plays a key role in the versatility of the car’s handling characteristics. When simply coasting along, the individual wheels are selectively raised or lowered to compensate for unevenness and undulations in the road surface – the result of a symbiosis between the navigation system’s digital predictions and the active chassis’ sophisticated control and actuation systems. Mounted on aerodynamically styled 23-inch alloy rims, the 285/30 tires strike a perfect balance between suitability for long-distance trips thanks to minimal rolling resistance and a sporty, active driving style with high longitudinal and lateral acceleration.

Design Sketch

The exterior: reverence without retro

When it comes to their footprint – 5.23 meters in length versus 5.19; a width of 1.85 versus 2.00 meters – it is easy to see the similarity between the legendary Horch 853 convertible and the Audi skysphere. A striking difference, on the other hand, can be found in their height – the legendary Horch, with its iconic design, towered up to 1.77 meters depending on the body shape, while its autonomous descendant, the Audi skysphere, ducks down to the road in Sport mode at 1.23 meters flat, with an optimized center of gravity and aerodynamics. The concept car pays its respects to the classic model without merely remaining a retro imitation.

After all, apart from its dimensions, it’s the lines that make a real difference. With its wide curved and flared wheel arches typical of the brand, the skysphere emphasizes the wide track – a visible indication of its dynamic talents. Viewed from the side, the proportions are impressive with a long hood and – especially at the front – a short overhang. The surfaces of the wheel arches and front hood are organically curved. The rear end was developed in a wind tunnel and combines elements of a speedster and a shooting brake with large glass surfaces in a traditional streamlined design. Two overnight bags designed specifically for the Audi skysphere find space under the glass, and are held in place with straps that are stretched in a crosswise pattern.

The front end – although no longer serving as a radiator grill – clearly features the brand’s typical Singleframe and the three-dimensionally designed, illuminated emblem with the four rings. The entire Singleframe and also the adjacent surfaces on the sides are designed with white LED elements to literally act as a stage for visual effects – both functional effects as well as moving welcome sequences when the vehicle is opened and closed.

Detail

Gentle dimming and a structured, rhythmically pulsating light produce an elegant effect. The daytime running lights in the side front sections, in turn, give the lighting units a resolute, focused “gaze.” If the wheelbase is changed, the LEDs in the front and rear display a specially composed dynamic sequence.

The rear end is also dominated by a digitally controlled LED surface that extends across the entire width of the vehicle. Countless red LEDs are scattered like rubies across the vertical rear surface. Reflections create dynamic lighting and shadow effects when the lighting units are switched on and off.

Upon changing the wheelbase and thus the operating mode from GT to Sport, the light signature also changes and sends a clear indication of the changed character of the Audi skysphere concept, particularly in the area around the Singleframe.

A characteristic feature of the side view are the rocker panels, which seem to protrude into the rear wheel arch – a necessary feature when varying the wheelbase actually pushes it backwards. The rocker panel is attached to the front end of the car, and as it moves, the panel also slides to the rear under the fixed door. In the process, the wheelbase is reduced from the standard size of an A8 L to the significantly more compact size of the curve-compatible Audi RS 5 – 25 centimeters make all the difference. And not just technically, but also visually and, above all, in terms of the driving experience.

There’s no doubt that the Audi skysphere concept has two personalities – a GT and a luxury sports car. The key differences, however, can only be enjoyed in the interior, because here, behind the rear-hinged and wide-opening doors, the Audi skysphere offers highly contrasting experiences.

The interior: two spheres of experience in one

When it comes to the three upcoming concept cars Audi skysphere, Audi grandsphere, and Audi urbansphere, the brand is placing the space that surrounds the passengers (“sphere”) and which becomes an experience for them – the interior – at the center of its designs. This is because all three vehicles are designed for level 4 autonomous driving – meaning that in certain defined road and traffic situations, the driver can delegate complete responsibility to the car and no longer has to intervene.

As a result, control elements such as the steering wheel and pedals can be swiveled into an invisible position and thereby completely removed from the interior. And passengers, including the one in the front left seat, can enjoy a new form of freedom – the freedom to relax in the open air, enjoy the scenery and the wind, or interact with the Internet and the world thanks to the connection with the digital ecosystem in the Audi skysphere.

Free of controls, the interior appears as a light, spacious environment, inspired in many areas by the Art Deco universe. The comfortable seats boast the visual elegance of designer furnishings, yet they fulfill the functions of an car seat in driving mode without any compromises – side support and safety features are part of the package. They are upholstered in sustainably produced microfiber fabric and, thanks to their variable position in the interior, offer the kind of freedom to move and legroom that can otherwise only be experienced when flying first class on an airplane. Environmentally certified eucalyptus wood and synthetically produced imitation leather are other sustainably manufactured materials that contribute to creating an unparalleled experience in the vehicle’s interior.

Should the Audi skysphere concept be used in driver-operated mode, then the interior transforms into an ergonomically perfect driving machine cockpit. Together with the chassis and body, the instrument panel and the monitor panel on the center console also move to the rear. The driver finds all the controls, including the steering wheel and pedals, in the position that best suits them.

Large touch monitor surfaces – 1415 mm wide, 180 mm high – on the dashboard and in the upper area of the center console are used to operate the vehicle and infotainment systems. In Grand Touring mode, this can be used to display content from the Internet, video conferences, or streamed movies. Small touch panels in the doors are used to operate the air conditioning.

A high-quality sound system – befitting of this luxury convertible – delivers concert hall audio quality even when the vehicle is in motion. The speakers are hidden behind the door panels; a few more in the rear interior wall even produce surround sound. The shape of the headrests prevents turbulence and also annoying wind noise.

The vehicle experience: luxury without limits

Audi skysphere, Audi grandsphere, and, coming in 2022, Audi urbansphere are the three concept cars that the brand with the four rings is using to showcase its vision of progressive luxury. In the process, Audi is creating a vehicle experience that goes far beyond the purpose of merely spending time in a car to get from point A to point B, and even far beyond the driving experience itself.

These concept cars feature a new design that ultimately reimagines the interior, the passenger compartment, as the center of the vehicle and no longer subordinates the passenger experience to the requirements of the technology. This is reflected in the variable layout of the interior, the disappearance of the controls, and the sheer expanse of the cabin. In Grand Touring mode, this not only allows both passengers to enjoy a smooth and pleasant journey, but also combines it with new service offerings. These can be used to access a variety of service options related to the current trip – such as designing a spectacular scenic route, as well as restaurant or hotel options.

Customized infotainment options are also available, such as linking the on-board streaming service to music and video providers used at home. And in a further step, Audi also aims to provide personalized and exclusive options for users of its luxury cars in the future – such as concerts, cultural events, or even sporting events that are only available upon special invitation. In this way, a vehicle like the Audi skysphere concept will become a platform for experiences that expand horizons beyond the mere ride in just a few years.