Gordon Murray Automotive reveals the T.50s Niki Lauda with the mission to deliver an on-track experience like no other car in history

• All-new T.50s Niki Lauda revealed: designed and engineered to offer “an on track experience like no other car to date.”

• Production limited to just 25 cars

• Designed, engineered and developed in parallel with the groundbreaking T.50 supercar

• Hundreds of components changed to optimise the car for track use

• Engineered without compromise, weighing just 852kg

• Powered by a 725bhp naturally aspirated V12 engine which weighs only 162kg and revs to 12,100rpm

• Named after legendary three-time F1 world champion and Gordon Murray’s former Brabham teammate, Niki Lauda

• Car unveiled on Niki Lauda’s birthday

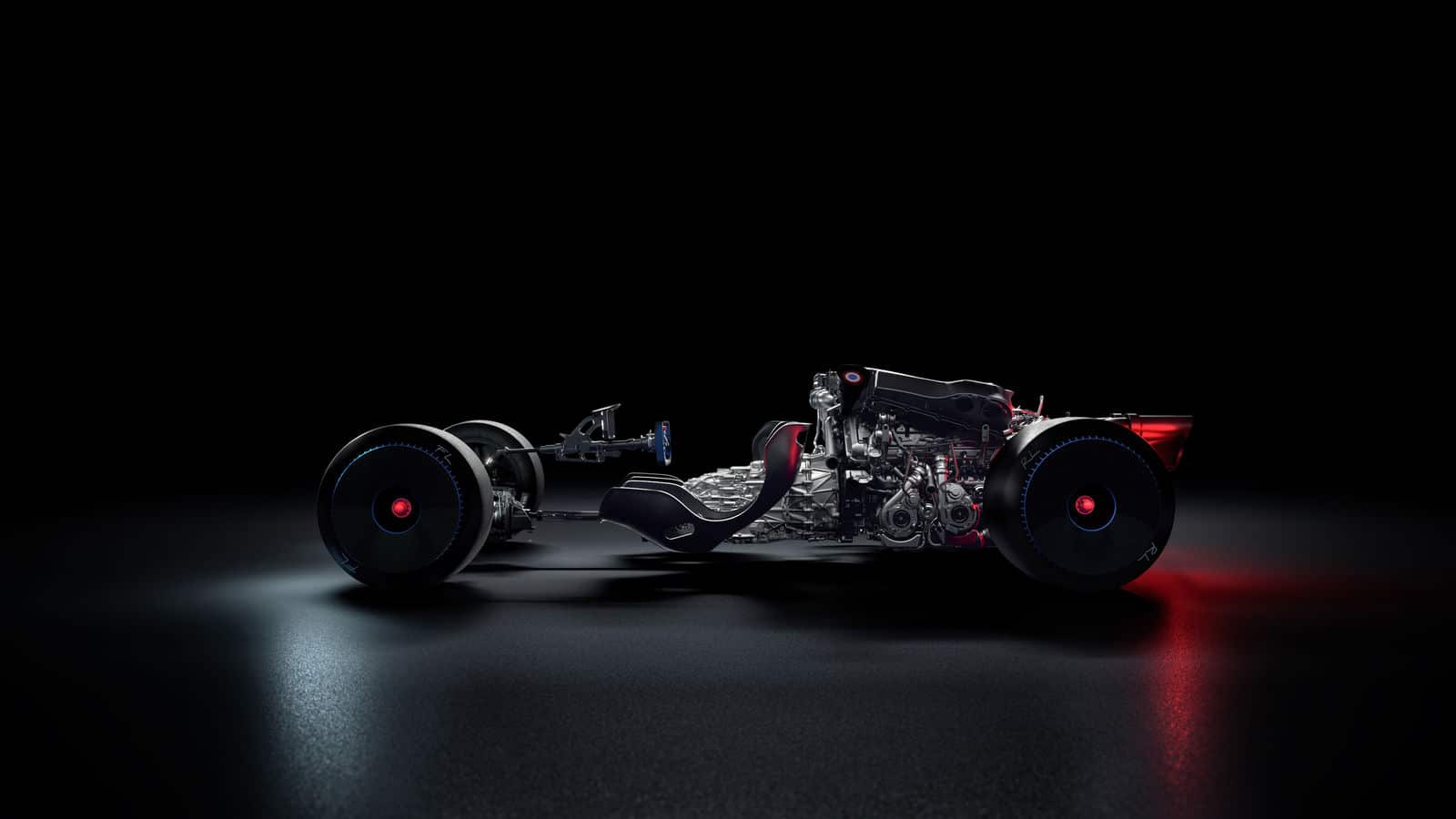

• Offers a unique and highly personalised ownership experience, witheach chassis named after one of Gordon Murray’s grand prix victories Gordon Murray Automotive has unveiled its T.50s Niki Lauda track-focused supercar for the first time. Developed in parallel with the T.50, the most driver-centric supercar ever built, the T.50s Niki Lauda has been conceived, designed and engineered to offer the ultimate on-track driving experience. Like the T.50, the T.50s Niki Lauda has been designed and engineered without compromise but with an even more extreme specification. It weighs just 852kg and will be powered by a substantially redesigned version of the T.50’s Cosworth-engineered 3.9-litre V12, producing 725bhp, revving to 12,100rpm and going through a newlydesigned Xtrac six-speed paddle-shift gearbox. Advanced aerodynamics, aided by a 400mm rear-mounted fan, will produce up to 1500kg of downforce for optimum track

performance.

Just 25 T.50s Niki Lauda’s will be made, costing £3.1m (before taxes). Production will start in January 2023 at Gordon Murray Automotive’s Manufacturing centre in Dunsfold, Surrey, UK, after the run of 100 T.50 supercars is completed. Professor Gordon Murray CBE: “The T.50 is the ultimate road-going supercar, but I always dreamed of taking it one step further… to build a version that will deliver an ontrack driving experience like no other car in history. “When we created the McLaren F1 GTR it was developed from the F1 road car. From its inception the T.50s Niki Lauda, though, was designed in parallel with the T.50. For the T.50 our target was clear, to make the best driver’s car for the road. With the T.50s Niki Lauda it was equally clear, to make it the best driver’s car for the track. Putting it another way, we asked ourselves what would be the coolest thing to drive on track and create a track driving experience like no other car in history?”

“We had no interest in achieving the ultimate lap time or creating an over-tyred and over-downforced spaceship at the expense of driver involvement, because ultimately you have to possess an F1 driver level of skill and fitness to get the best out of them.” “Instead, I laid out some parameters to create the ultimate driver’s car and experience on track: a central driving position, a V12 just behind your ear revving to over 12,000rpm, producing over 700 horsepower and with an even faster response time than Vthe T.50, downforce limited to 1500kg and a weight of under 900kg. Plus the ability to turn up at any track, make a few basic checks and have fun, without the need for an

entire support crew.

“In my view it doesn’t get better than that and is driving in its purest form. The T.50s Niki Lauda will give a visceral connection between driver, car and track, the like of which has

not been experienced to date. “I can just imagine going round your favourite circuit, sitting in the middle with that unsilenced V12 screaming just behind you – the driving experience will be something special. With a power to weight ratio better than that of a naturally aspirated LMP1 car, it is also going to be searingly quick and, with such a low weight, will change direction like

an F1 car.

“With the direction of travel of the automotive industry, it’s hard to imagine that there will ever be another car quite like this. Especially not one with a central driving position, a

high revving naturally aspirated V12 engine and that is so lightweight. I believe it will go on to define its era.”

Design

Gordon Murray and the team have worked hard on the T.50s body design to achieve their aerodynamic performance targets, whilst retaining the T.50’s balanced and classic

proportions.

The dramatic aerodynamic features of the T.50s Niki Lauda instantly give away its performance potential. A striking central fin designed to enhance stability features a Niki

Lauda logo. At the rear, the distinctive 400mm fan from the T.50 is retained, accompanied by an even larger rear diffuser and a new delta wing. The rear grille features a T.50s badge and ‘Fan Car’ script.BThe aerodynamic elements continue at the front of the car. Barge boards are sculpted to improve airflow to the side ducts, which house the oil cooling systems for the engine and

transmission. A splitter and dive planes are also prominent and further reflect the car’s aero-influenced design. At the same time, the purity of the T.50 is not lost, creating a purposeful yet elegant look.

Owners will be able to individualise their T.50s through their choice of colours and liveries, so that no two cars will be alike. Professor Gordon Murray CBE: “The styling of the T.50s is completely aero driven, but still attractive. There’s not one body panel carried over from the T.50, but the road car has such a strong and classic shape that it still manages to shine through.”

Engine and transmission

The Cosworth-designed 3.9-litre V12 engine is a dramatically different version of the engine that powers the T.50. It is even more powerful and faster-revving too, delivering 711PS at 11,500rpm, on its way to a 12,100rpm rev-limit. At 178hp/litre, the specific power output of the T.50s Niki Lauda’s V12 exceeds that of the all-conquering Cosworth DFV Formula One engine. The power-to weight ratio of 835PS/tonne betters that of a naturally aspirated LMP1 car.

The T.50s Niki Lauda’s engine is fed by a newly-designed, roof-mounted, highperformance RAM induction airbox (which can increase maximum power to 725bhp). The maximum torque figure is 485Nm, produced at 9,000rpm. A newly-developed, bespoke, straight-through exhaust system also takes the engine sound to a new level. Right through the rev-range it promises to be one of the greatest and most characterful sounding cars ever made.

The state of the art V12 pushes the boundaries of engine design even further, with many new components. Changes include completely revised cylinder heads and camshafts,

plus a higher compression ratio of 15:1. Through meticulous attention to detail, this new iteration of the Cosworth GMA V12 weighs just 162kg, 16kg less than what was already the lightest road-going V12 engine ever. The weight-saving measures extend to the intake, exhaust and control systems, as well as the engine itself. All the valves are made from titanium, while there is no variable

valve timing due to the additional weight of the geartrain and electronic control system.

A simpler induction system features 12 throttle bodies on top of the engine, fed directly by the racing-style air box. The exhaust system does without catalytic converters, has

thinner Inconel walls and, with only track noise limits to meet, benefits from smaller silencers.

A bespoke Xtrac IGS (Instantaneous Gearshift) six-speed paddle shift gearbox is fitted, designed to fit the exacting packaging and weight demands of the T.50s. As part of Xtrac’s efforts to minimise weight wherever possible, even the gears are lighter, contributing to a 5kg total weight reduction. Both the gearbox and the clutch are electronically actuated. Ratios have been chosen to optimise on-track performance and driver enjoyment and engagement, delivering a top speed of approximately 200-210mph. A set of closer ratios optimised for shorter circuits will also be offered, allowing owners to make the most of all six gears via the steering column-mounted paddles. In this configuration, the T.50s Niki Lauda will reach around 170mph flat-out.

Chassis, body and suspension

The T.50s Niki Lauda is built around a specially developed, lightweight carbon fibre monocoque. Optimised for weight reduction and structural rigidity, it is constructed using advanced part-binding technology, with carbon fibre wrapped around a honeycomb aluminium core. This stiffness and strength also contributes to the T.50s’s exceptional occupant safety, with precisely engineered deformable areas. Passengers are further protected by an F1- style ‘passenger safety cell’. Exterior body panels, all unique to the T.50s, are also made from ultra-lightweight

carbon fibre. Windows and screens use glazing that has been further reduced in weight from the road car specification. For exceptional levels of confidence inspiring on-track dynamics, the T.50s Niki Lauda utilises the same forged aluminium front and rear double wishbone suspension system as the T.50. However, the springs, dampers and anti-roll bar have been respecified to optimise track performance, while the ride height has been lowered to 87mm at the front and 116mm at the rear.

As part of the Trackspeed package, the T.50s Niki Lauda’s chassis can be adjusted to find the ideal setup for its owner. Both the chassis settings and the aerodynamics are

fully adjustable.

Steering

The T.50s Niki Lauda retains the T.50’s rack and pinion steering, but with a revised steering ratio.

Brakes

The Brembo carbon ceramic discs of the T.50 are carried over to the T.50s Niki Lauda (370mm x 34mm front/340mm x 34mm rear), with six-piston front callipers and fourpiston rear callipers. The braking system and aerodynamics combine to produce incredible deceleration of 3.5G. To ensure the brakes maintain their phenomenal performance throughout a track session, new ducting around each wheel is designed to improve brake cooling.

Wheels and tyres

The T.50s sits on unique and exceptionally light magnesium forged 18-inch wheels, weighing less than 6kg each, with Formula One-style lightweight wheel hubs and a centre lock attachment. The wheels are wrapped in Michelin slick tyres, measuring 250mm wide at the front (25/64 18”) and 300mm wide at the rear (30/68 18”). A wet option is also provided.

Aerodynamics

The T.50s Niki Lauda has completely new aero, which combines to create 1500kg of downforce. This includes a new 1,758mm-wide, rear-mounted delta wing, the design of which was inspired by the front wing on Murray’s 1983 Brabham BT52 Formula One car and is just as effective today as it was then. The front of the T.50s features a splitter with a central aerofoil section, which generates huge load figures to balance out those from the rear wing. The splitter’s central channel reduces the car’s sensitivity to pitch while allowing airflow under the car to continue to

drive the central diffuser section, keeping the efficiency of the entire aero package high.

Dive planes include horizontal elements paired with a vertical duct to manage wheel arch pressures and tyre wake, reducing drag and improving efficiency. A pair of NACA ducts have been perfectly positioned on the front clam shell in a region of high pressure and where the thin boundary layer is ideal for cooling the large front brakes. A central fin stretching from the top of the roof to the rear lip of the car has also been added for increased yaw stability. The large vertical face is presented to the airflow during high-speed cornering and helps counteract the momentum of the car towards the outside of the corner.

To further improve airflow and accommodate the central fin, the oil cooling systems for the engine and transmission are now located in side ducts. By placing these systems

lower in the car, this helps to optimise its centre of gravity.

With the powertrain coolers located directly downstream of the front wheels, barge boards have been added to manage the turbulent wake emanating from the front wheel

arches, ensuring a clean flow of air to the side ducts.

The T.50s Niki Lauda retains the same 400mm ground-effect fan as the T.50, but here it runs in a single High Downforce mode, spinning at 7000rpm. The T.50s also has much

simpler ducting, with a permanently open duct running down to the redesigned rear diffuser.

Like the chassis, the T.50s Niki Lauda’s aerodynamics can be adjusted to suit its owner’s preferences, adding or removing downforce as required. To balance the car’s aero, the front diffusers are adjustable, as is a slotted flap on the rear wing. The highspeed balance can be further honed through changes to the car’s ride height.

In the optimum configuration, when a particular race circuit demands it, up to 1500kg of downforce will be achievable. However, the car’s aerodynamics have been carefully

designed to ensure that the T.50s Niki Lauda’s performance remains accessible and exploitable regardless of the driver’s experience.

Professor Gordon Murray CBE: “When we first ran the CFD we were already ahead of our downforce target. At one point we were achieving 1,900kg of downforce, but we

backed it off to 1,500kg to make the car more manageable for the owners.”

Interior

The dihedral doors lift to reveal a race-car oriented cabin. The T.50s Niki Lauda retains the driver-focused central seating position of the T.50, giving the driver an unhindered view of the track ahead and allowing perfect placement. The driver sits on a full racing carbon fibre seat with fore and aft adjustment, and is secured with a six-point harness. The T.50s is a two-seater with a fixed passenger seat to the left of the driver, complete with a four-point harness. In place of the seat on the right is a fire extinguisher system. Occupying the space formerly taken up by the passenger footwell is a vertical switch gear panel similar to that found on the legendary McLaren F1 GTR. Should the owner wish, the car can be ordered without a passenger seat to save further weight and create an even more focused feel.

The rectangular carbon fibre steering wheel is a lesson in simplicity, featuring only the key controls that the driver needs. This includes buttons for the traction and launch control, as well as the car-to-pit/driver-to-passenger radio and to select neutral. The slim, uncluttered design is influenced by Murray’s racing experience. Professor Gordon Murray CBE: “I used to make my drivers take their watches off, partly for weight, but also because it adds to the steering inertia. Big wheels with lots of switches are quite heavy from a steering inertia point of view, so for the T.50s I wanted

to keep the wheel small, clean and simple.” To avoid unnecessary distractions, the T.50s features a single digital screen. This displays essential vehicle and engine data, as well as aero info, the gearchange indicator, telemetry, lap time, tyre pressures/temperatures, G-forces and a camera video feed.

Driver comfort was another priority for Murray when designing the T.50s, which maintains the same spaciousness and visibility as the road car. This makes the T.50s Niki Lauda a uniquely usable track car, despite its incredible performance. Professor Gordon Murray CBE: “Engineering the ultimate track-focused supercar has to start with the driver. It was essential that we retained a central driving position, with every control arranged within easy reach and with no distractions or unnecessary information on display. And in my opinion, you don’t get a better view than that from the central driving position and one which allows you to place the T.50s Niki Lauda with millimetre precision on any circuit. You are left with nothing to take away the purepleasure of pushing this car as hard as you can on your favourite race circuit.”

“Racing drivers are often uncomfortable, they just put up with it because they’re trying to win a race. The McLaren F1 had a really nice driving position and good visibility and I think that helped the guys at Le Mans because it made it more comfortable for them. In the T.50s, the driving position ergonomically is just about as good as it gets. This is a

car you can drive all day.”

Named after a racing legend

The T.50s Niki Lauda has been named after legendary three-time Formula One World Champion, Niki Lauda. Professor Gordon Murray CBE: “The T.50s is named in honour of Niki to commemorate his famous win with the Brabham BT46B fan car in the 1978 Swedish Grand Prix. Niki was a great racing driver and he was also a good friend and it is absolutely fitting that

we are launching the T.50s Niki Lauda on his birthday. Niki would have appreciated the innovation and engineering detail in our car.”

The Lauda family said: “We are proud that Gordon Murray Automotive has named its new car after Niki. He would have been extremely honoured to have been associated with a car designed and engineered by Gordon, with whom he had such a long association and friendship.” Each chassis to be named after one of Gordon Murray’s F1 race wins Additionally, each of the 25 cars’ chassis will be individually named after one of Gordon Murray’s grand prix wins on different circuits. The first car will be designated Kyalami 1974 and further cars will be named after the 24 subsequent wins, in chronological order. Each car will also come with a specially commissioned book about the race that it is named after, with Murray’s view and memories of the victory.

Professor Gordon Murray CBE: “Each car will carry its own individual story, being forever linked to the grand prix victory it is named after. The T.50s is inspired by my love of motorsport, so it seemed entirely fitting to create this special connection to iconic races from the past.”

Customer experience

T.50s Niki Lauda buyers will receive a bespoke and personalised service, from the first expression of interest, through the specification, manufacturing and handover periods, as well as throughout the entire duration of their ownership. Each of the 25 individually specified cars will be unique, both in terms of setup and in the choice of colours and liveries.

A Trackspeed package will also be included which comprises both engineering support and all the equipment needed to run the car at a track, including a full set of pit tools and

refuelling equipment. Customers will be invited to a track day to have both chassis and aerodynamics set-upfor them to suit their driving style and experience. Owners will also benefit from a day’s

on-track tuition in the T.50s Niki Lauda to enable them to get the most from their car, and there will be a day’s tuition for the owner’s nominated technician to help them

prepare the car for track driving days. Additionally, there will be ongoing engineering support to allow owners to run their car at events and track days around the world. Gordon Murray Automotive is planning its own special events for T.50s Niki Lauda owners in future.

Gordon Murray Automotive are working closely with Stefan Ratel and his SRO organisation towards creating a GT1 sports club, which will provide exclusive track days aligned with the GT World Challenge Europe events on some of Europe’s most prestigious circuits. This is a first step with a view to creating a future supercar race

series.

Professor Gordon Murray CBE: “It was essential to me that the T.50s Niki Lauda is easy to live with and enjoy. You will own the car, you will be completely in control of where

and when you enjoy it. My vision is that owners will take it to a circuit, check the tyre pressures, climb in, fire it up and have fun. That’s the way it should be.”

-EndsAbout

Gordon Murray Automotive

Gordon Murray Automotive creates exclusive low volume sports cars – the T.50 supercar will be the brand’s first model with customer cars built from January 2022. Its sister car, the

T.50s Niki Lauda goes into production one year later The company is a sister company to Gordon Murray Design and was first announced in November 2017 during an exhibition,

named ‘One Formula’, which celebrated Murray’s 50 years of car design.

About Professor Gordon Murray, CBE

Having spent 20 years as Technical Director to two Formula One teams from 1969-1990 Gordon Murray has a wealth of technical, design and engineering experience. At Brabham he was instrumental in two world championship wins (1981 and 1983) before three consecutive championship wins with McLaren Racing (1988, 1989 and 1990). In 1990 – after 50 Grand Prix wins – Gordon moved away from Formula One to concentrate on establishing a new company for the group, McLaren Cars Limited.

His first project there, the F1 road car, is still regarded as one of the world’s best-engineered cars. A racing version won two world sports car championships and the Le Mans 24-hour

race in 1995. McLaren Cars then completed several other successful projects culminating in the Mercedes-Benz SLR McLaren. Gordon left McLaren in 2005 to set up a Gordon Murray Design Ltd (in 2007), of which he is Chairman. The innovative British company is a world leader in automotive design, and reverses the current industry trend for sub-contracting by having a complete in-house capability for design, prototyping, and development.

In 2017, Gordon Murray Design celebrated the company’s 10-year anniversary along with that of the iStream® manufacturing process at a special event, named ‘One Formula’. Gordon also marked the 25th production anniversary of the McLaren F1 road car, and his 50th year of design and engineering.

In May 2019, Professor Murray was made a Commander of the British Empire (CBE) by the Duke of Cambridge, Prince William, in recognition of his contributions to the motorsport and

automotive sectors over the past 50 years.

Social media

Instagram: gordonmurrayautomotive | Facebook: @gordonmurrayautomotive | Twitter:

@PlanetGMA

Media contact

For further information, images, or comment, email:

media@gordonmurrayautomotive.com

Sales enquiries

For sales enquires email:

enquiries@gordonmurrayautomotive.com

Social media

Instagram: gordonmurrayautomotive | Facebook: @gordonmurrayautomotive | Twitter:

@PlanetGMA

Media contact

For further information, images, or comment, email:

media@gordonmurrayautomotive.com

Sales enquiries

For sales enquires email:

enquiries@gordonmurrayautomotive.com