Ingolstadt, July 7, 2020 – From a technical perspective, they are identical twins, but in terms of their shape, they each have their own unmistakable and characteristic features: The Audi Q4 e-tron concept gave visitors to the 2019 Geneva Motor Show a taste of the first compact electric SUV from Audi. With the Q4 Sportback e-tron, the brand is now presenting the second model of the product line that will go into production in 2021 as an SUV Coupé. This gives potential Q4 customers the opportunity to start thinking about which version they prefer roughly a year before the first vehicles will be delivered: the versatility and robustness of the classic SUV or the dynamic elegance of the Coupé variant. The dimensions of the two Q4 models are almost identical: With an exterior length of 4.60 meters (15.1 ft) and a height of 1.60 m (5.2 ft), the Sportback is one centimeter (0.4 in) longer and flatter. The Q4 variants are identical in terms of their width of 1.90 m (6.2 ft) and their wheelbase of 2.77 meters (9.1 ft).

Audi Q4 e-tron concept

Static photo, Color: solar sky

Audi Q4 Sportback e-tron concept

Static photo, Color: kinetic grey

- Audi presents Coupé variant of Q4 e-tron as a concept car

- Versatile efficiency technologies enable ranges over 500 kilometers (310.7 mi)

- Production version to be launched in 2021 as the Audi brand’s seventh electric model

The two concept cars, which are already offering a clear look ahead at the top-of-the-range engine line-up of the coming series production model, also have the same drive technology. Two

electric motors mobilize 225 kW of system output in the Q4 and Q4 Sportback e-tron concept.

As is typical for Audi, the driving power is brought to the road with quattro all-wheel drive. Thanks to excellent traction, both versions of the Q4 accelerate from zero to 100 km/h

(62.1 mph) in just 6.3 seconds. Top speed is restricted to 180 km/h (111.8 mph).

Audi Q4 e-tron concept

Static photo, Color: solar sky

Audi Q4 Sportback e-tron concept

Static photo, Color: kinetic grey

A large battery with a capacity of 82 kilowatt hours takes up almost the entire space in the underbody area between the axles. The range of over 450 kilometers (279.6 mi) – in line with the WLTP standard – sets the benchmark in its class. Versions with rear-wheel drive will offer a range of over 500 kilometers (310.7 mi) in accordance with WLTP. The technology of the Q4 etron concept is provided by the modular electrification platform (MEB), which will be integrated in numerous electric vehicles produced by the Volkswagen Group in the future, from the compact class to the superior medium-size class. The Audi Q4 Sportback e-tron concept offers an advance look at what will already be the seventh series production electric vehicle that the

manufacturer will introduce by 2021.

The silhouette of the Sportback slopes downward to the back in a subtle and dynamic curve. The roof line transitions into the significantly inclined D-pillars and ends in a horizontal spoiler at the

level of the lower window edge. As a result, the future Audi Q4 Sportback appears much longer than its sister model, the Q4 e-tron concept. The striking broad light band that connects the two lamp units on the rear end of the Audi Q4 Sportback e-tron concept was incorporated to reflect an element of the Audi Q4 e-tron concept.

It is clearly visible even here that these two models belong to the same e-tron family, as the close relation to the e-tron Sportback* is obvious. This also applies to the inside of the lights, where the significant sweep of the LED segments is also reminiscent of an element of the older brother. The striking design of the bumper diffuser unit with its horizontal slats and the illuminated e-tron logo in the middle is an element that the two Q4 versions share.

When looking at it from the front, the Singleframe with the four rings brand logo identifies the Q4 Sportback e-tron concept as an Audi vehicle. And it will take no more than two glances to see

that this is an electric Audi: Like the first production Audi with electric drive, the new concept vehicle also features a structured closed surface within a broad, almost upright octagonal frame

in place of a traditional radiator grille.

The prominently modeled fenders of all four wheels are a further classic Audi design feature that has distinguished the brand since the legendary original quattro 1980. The widened features of

the Q4 e-tron concept and Q4 Sportback concept are designed to be highly organic and flowing, and they add a characteristic touch to the side view. The accentuation of the rocker panel area between the axles, where the battery and thus the powerhouse of this SUV is located, is a typical feature of the e-tron. Large 22-inch wheels leave no doubt as to the potential of the newest

member of the Audi family.

The Q4 Sportback e-tron concept is painted in the new kinetic grey color, a light metallic and pearl effect color that takes on a distinct greenish tinge depending on the angle of the light. In

contrast, the lower sections of the body are painted in a dark grey color. This segmentation emphasizes the width and horizontal orientation of the vehicle’s architecture.

Sense of spaciousness – the interior With its dimensions, the Audi Q4 Sportback e-tron concept also takes its position in the upper third of the compact class. Its road space requirements qualify the electric SUV as an agile allrounder.

In terms of the interior, by contrast, its wheelbase of 2.77 meters (9.1 ft) puts it at least one class higher. As there is no transmission tunnel restricting the space, the Q4 Sportback

e-tron concept offers unsuspected spaciousness and comfort, especially in terms of legroom at the front and even more in the rear.

Audi Q4 e-tron concept

Static photo, Color: solar sky

Audi Q4 Sportback e-tron concept

Static photo, Color: kinetic grey

The color scheme emphasizes the sense of spaciousness. While light, warm colors dominate the upper section of the cabin, the dark carpet in the floor section provides a contrast. The headlining, the window pillars and the upper section of the door rail and dash panel are fitted with white and beige microfiber textiles. Sustainability is the top priority not only in terms of the

electric drive in the Audi Q4 and Q4 Sportback: The floor covering is made of recycled materials. Instead of chrome-plated metal decor frames, the surfaces are covered with a high-quality multi-layer paint finish. The painted frosted Plexiglas on the applications creates an intensive depth effect. Four seats with integrated head restraints are upholstered with comfortable Alcantara material manufactured with exquisite workmanship. Double seams stitched with thick yarn adorn the upholstery.

The display of the Audi virtual cockpit with the most important display elements for speed, charge level, and navigation is located behind the steering wheel. The large-format head-up

display with an augmented reality function is a new feature. It can display important graphical information, such as directional arrows for turning, directly on the course of the road.

Control panels designed as touch elements on the steering wheel spokes can be used to select frequently used functions. In the middle above the center console, there is a 12.3-inch

touchscreen via which the infotainment and vehicle functions are displayed and operated.

It is tilted toward the driver for greater ease of operation. A strip of buttons for controlling the air conditioning is located below it. As the center console does not need to hold functional elements such as a gear lever or hand brake actuation elements, it is designed as a spacious stowage compartment that includes a cell phone charging cradle. There is a horizontal area in high-quality design into which the selector button for the transmission mode is integrated and that also serves as a cover for the front section of the console. In addition to the conventional lower storage compartment, the doors now provide the possibility to store bottles in the specially molded upper section, where they are

easy to reach.

Dynamic photo,

Color: kinetic grey

Efficient performer: drive system and suspension

The modular electrification platform (MEB) offers a broad range of drive variants and power levels. The performance version of the electric drive is installed in the Audi Q4 Sportback e-tron

concept. The front and rear axles are each powered by an electric motor – this Q4 Sportback is a quattro. There is no mechanical connection between the axles. Instead, an electronic control

ensures that the torque distribution is coordinated optimally, and it does so in fractions of a second. That enables the SUV Coupé to achieve optimum traction in all weather conditions and on any type of surface.

In most cases, the Q4 Sportback e-tron concept mainly uses its rear electric motor, a permanently excited synchronous motor, in order to achieve the highest efficiency. For reasons

of efficiency, the drive torque is generally distributed with a rear-axle bias.

If the driver demands more power than the rear electric motor can supply, the electric all-wheel drive uses the front asynchronous motor to redistribute the torque as required to the front axle.

This also happens predictively even before slip occurs in icy conditions or when cornering fast, or if the car understeers or oversteers.

The electric motor in the rear end has an output of 150 kW and mobilizes a torque of 310 newton meters (228.6 lb-ft); the front motor supplies the front wheels with up to 75 kW

and 150 newton meters (110.6 lb-ft). The system output is 225 kW. The battery in the vehicle floor stores 82 kilowatt hours, which allows for a range of more than 450 kilometers (279.6 mi)

according to the WLTP standard. The battery is charged with a maximum of 125 kilowatts. It therefore takes little more than 30 minutes to reach 80 percent of the total capacity.

However, the recipe for this excellent range involves far more than just an energy storage unit with a large capacity. Just like the first member of the family, the Audi Q4 e-tron concept, the

Audi Q4 Sportback also presents itself as an efficiency virtuoso, starting with the low aerodynamic drag of the body, whose drag coefficient is 0.26 and therefore 0.01 below that of

the Q4 e-tron SUV. The compact electric product line also features a sophisticated recuperation strategy, leaving out no possibility for optimizing its range. The complex thermal management of the drive and battery, which involves a CO2 heat pump, also contributes to this.

Static photo,

Color: Kinetic grey

Sporty, precise handling

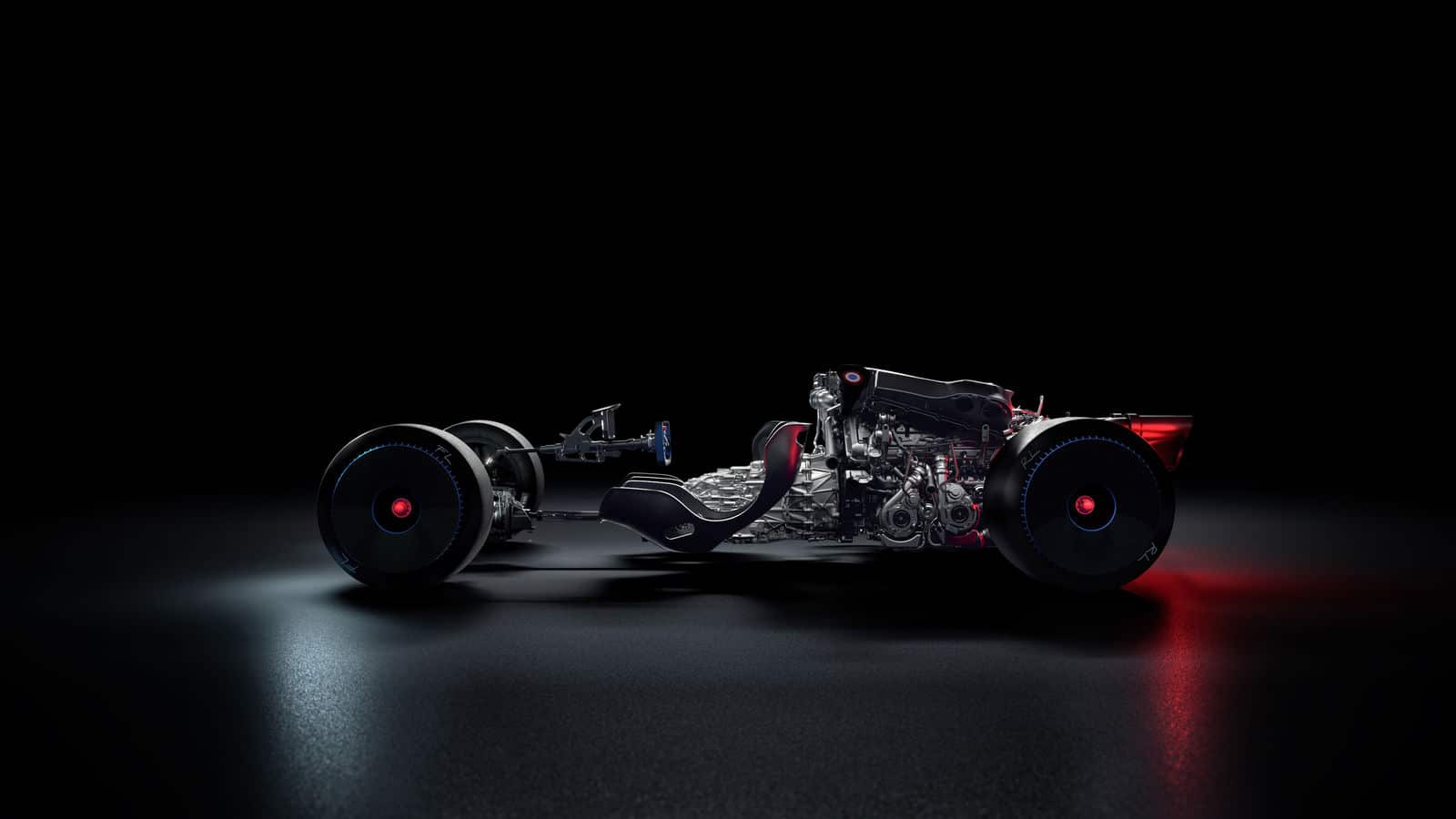

A key factor for the sporty character and outstanding transverse dynamics is the low and central position at which the drive components are installed. The high-voltage battery system is

optimally matched to the dimensions of the Audi Q4 Sportback and is located between the axles in the form of a flat, broad block beneath the passenger compartment. The battery system weighs 510 kilograms (1,124.4 lb). The center of gravity of the Audi Q4 Sportback e-tron concept is therefore at a similar level to that of a sedan with a conventional drive system.

Axle load distribution is perfectly balanced at almost 50:50. The front wheels of the Q4 Sportback e-tron concept are guided on a MacPherson axle with adaptive dampers. In the rear,

there is a multi-link axle with separate springs and adaptive dampers.

The modular electrification platform MEB: the base

MLB, MQB – modular longitudinal platform and modular lateral platform: These component systems for vehicle development represent a great success story in all segments of Audi and the Volkswagen Group. Previous platforms were designed primarily for the use of combustion engines. What is new and different about the modular electrification platform: It was designed specifically and exclusively for automobiles with electric drive systems. Axles, drives, wheelbases and the interaction between all components are selected and adapted specifically for e-mobility.

The placement of the large-volume battery units and their geometry can therefore be optimized without having to make concessions to other drive concepts that must always be taken into

account in the MLB and MQB. At the same time, the MEB opens up a huge synergy potential. This platform serves as the basis primarily for electric cars in the high-volume A segment. It allows the best technology available to be developed jointly across brands and used in many different electric cars. The MEB thus also helps electric mobility to break through even in the particularly price-sensitive compact segment.

E-initiative: more than 20 electric drive models by 2025

The brand with the four rings launched its electric offensive with the world premiere of the allelectric SUV Audi e-tron* in September 2018. By 2025, Audi will offer more than 20 automobiles

with all-electric drive in the most important markets worldwide and achieve roughly 40 percent of its sales with electrified models. The SUVs within this portfolio include the e-tron* and the etron

Sportback*. In addition, there will be a range of models with classic body layout such as Avant and Sportback. The range will cover every relevant market segment from the compact

class to the luxury class.

Fuel consumption of the models named above:

(Fuel consumption and CO2 emission figures given in ranges depend on the equipment selected)

Audi e-tron 50 quattro

Combined electric power consumption in kWh/100 km (62.1 mi): 26.6–22.4 (WLTP);

24.3–21.9 (NEDC)

Combined CO2 emissions in g/km (g/mi): 0

Audi e-tron 55 quattro

Combined electric power consumption in kWh/100 km (62.1 mi): 26.4–22.4 (WLTP);

23.1–21.0 (NEDC)

Combined CO2 emissions in g/km (g/mi): 0

Audi e-tron Sportback 50 quattro

Combined electric power consumption in kWh/100 km (62.1 mi): 26.3–21.6 (WLTP);

23.9–21.4 (NEDC)

Combined CO2 emissions in g/km (g/mi): 0

Audi e-tron Sportback 55 quattro

Combined electric power consumption in kWh/100 km (62.1 mi): 26.0–21.9 (WLTP);

22.7–20.6 (NEDC)

Combined CO2 emissions in g/km (g/mi): 0

Audi

MediaInfo

6/6

The specified fuel consumption and emission data have been determined according to the measurement procedures prescribed by law. Since September 1, 2017, certain new vehicles are already being typeapproved according to the Worldwide Harmonized Light Vehicles Test Procedure (WLTP), a more realistic test procedure for measuring fuel consumption and CO2 emissions. Starting on September 1, 2018, the New European Driving Cycle (NEDC) will be replaced by the WLTP in stages. Owing to the more realistic test conditions, the fuel consumption and CO₂ emissions measured according to the WLTP will, in many cases, be higher than those measured according to the NEDC. For further information on the differences between the

WLTP and NEDC, please visit www.audi.de/wltp.

We are currently still required by law to state the NEDC figures. In the case of new vehicles which have been type-approved according to the WLTP, the NEDC figures are derived from the WLTP data. It is possible to specify the WLTP figures voluntarily in addition until such time as this is required by law. In cases where the NEDC figures are specified as value ranges, these do not refer to a particular individual vehicle and do not constitute part of the sales offering. They are intended exclusively as a means of comparison between different vehicle types. Additional equipment and accessories (e.g. add-on parts, different tire formats, etc.)may change the relevant vehicle parameters, such as weight, rolling resistance and aerodynamics, and, in conjunction with weather and traffic conditions and individual driving style, may affect fuel consumption, electrical power consumption, CO₂ emissions and the performance figures for the vehicle.

Fuel consumption and CO2 emissions figures given in ranges depend on the tires/wheels used and chosen equipment level. Further information on official fuel consumption figures and the official specific CO2 emissions of new passenger cars can be found in the “Guide on the fuel economy, CO2 emissions and power consumption of all new passenger car models,” which is available free of charge at all sales dealerships and from DAT Deutsche Automobil Treuhand GmbH, Hellmuth-Hirth-Str. 1, 73760 Ostfildern, Germany, or

under www.dat.de.

The Audi Group, with its brands Audi, Ducati and Lamborghini, is one of the most successful manufacturers of automobiles and motorcycles in the premium segment. It is present in more than 100 markets worldwide and produces at 16 locations in 11 countries. 100 percent subsidiaries of AUDI AG include Audi Sport GmbH (Neckarsulm, Germany), Automobili Lamborghini S.p.A. (Sant’Agata Bolognese, Italy) and Ducati Motor

Holding S.p.A. (Bologna, Italy).

In 2019, the Audi Group delivered to customers about 1.846 million automobiles of the Audi brand, 8,205 sports cars of the Lamborghini brand and 53,183 motorcycles of the Ducati brand. In the 2019 fiscal year, AUDI AG achieved total revenue of €55.7 billion and an operating profit of €4.5 billion. At present, 90,000 people work for the company all over the world, 60,000 of them in Germany. Audi focuses on sustainable products and technologies for the future of mobility.