-

El segundo auto conceptual de Polestar se basa en el lenguaje de diseño Precept

-

La plataforma de aluminio a medida muestra calidad y rigidez

-

Las ambiciones de sostenibilidad y tecnología dan los siguientes pasos hacia una mayor circularidad con monomaterial termoplástico de poliéster reciclado y etiquetado de aluminio

-

Dron cinemático autónomo mezcla innovación con diversión

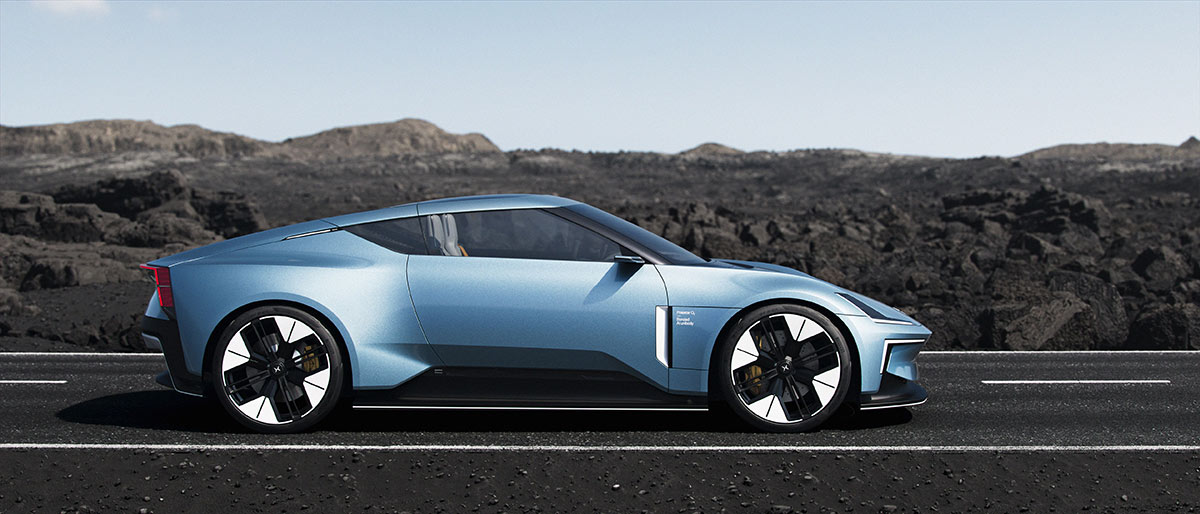

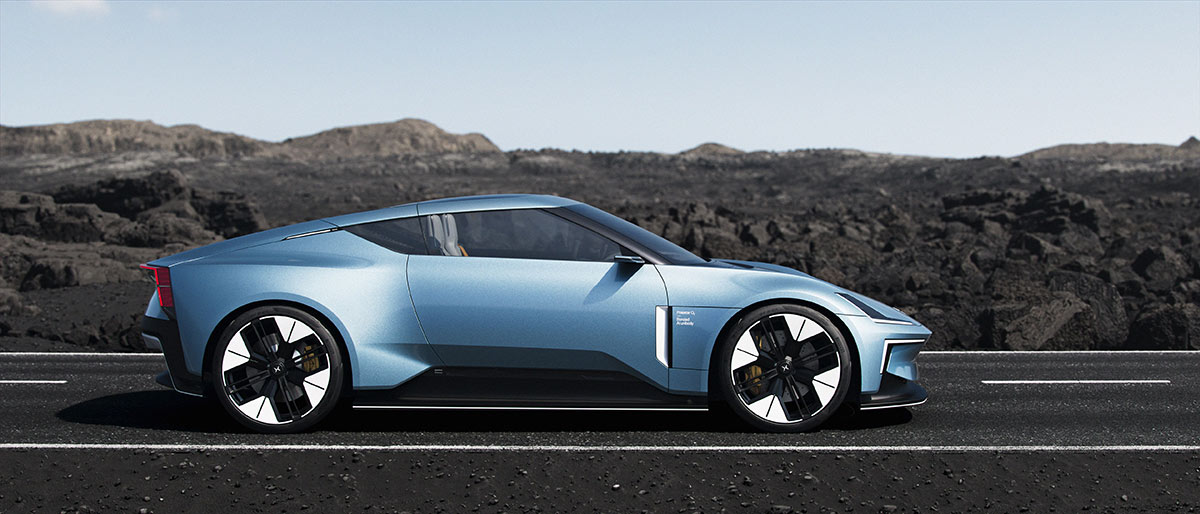

El concepto Polestar O₂ prevé una nueva era para los roadster eléctricos

GOTEMBURGO, SUECIA – 2 de marzo de 2022. Polestar, la marca de autos eléctricos de desempeño puro, ha revelado un nuevo auto conceptual que redefine los deportivos deportivos para la era eléctrica. Bautizado como Polestar O2, el descapotable de techo rígido es la visión de Polestar de un rendimiento descapotable y una experiencia de conducción emocionante, con todos los beneficios de la movilidad eléctrica.

“Polestar O2 es el auto héroe de nuestra marca”, comenta Thomas Ingenlath, CEO de Polestar. “Abre la puerta a nuestra cámara secreta de potencial futuro. Esta es una muestra de lo que podemos diseñar e ingeniar con el talento y la tecnología que tenemos internamente. Se ve increíble, y poder bajar el techo y no escuchar un motor promete una sensación magnífica”.

Dinámica

Maximilian Missoni, Jefe de Diseño de Polestar, dice: “Polestar O2 es nuestra visión de una nueva era para los autos deportivos. Al mezclar la alegría de conducir con la capota abierta con la pureza de la movilidad eléctrica, desbloquea una nueva combinación de emociones en un automóvil. Pero como con todos nuestros autos, somos más que carreras en línea recta. Es cuando giras el volante cuando comienza la verdadera diversión.

La experiencia de conducción en el Polestar O2 está diseñada para ser animada, ligera y llena de confianza. La previsibilidad y la alegría son fundamentales para una conducción emocionante y enérgica. El control estricto de la carrocería, la alta rigidez y la dinámica intuitiva son beneficios inherentes de la plataforma de aluminio adherido a medida, que se adaptó del Polestar 5, desarrollado internamente por el equipo de I+D de Polestar en el Reino Unido.

El concepto Polestar O₂ prevé una nueva era para los roadster eléctricos

La alta calidad y rigidez de la plataforma de aluminio adherido están orientadas hacia una mayor respuesta dinámica. La dinámica de manejo es tensa gracias también a los ángulos de balanceo pequeños y la amortiguación de alto balanceo, y la sensación de dirección ágil y directa es lineal, con una gran acumulación de par de dirección.

El concepto Polestar O₂ prevé una nueva era para los roadster eléctricos

Diseño

Claramente relacionado con el concept car Polestar Precept pero con su propio carácter distintivo, el aspecto del Polestar O2 muestra cómo el lenguaje de diseño en evolución de Polestar se puede adaptar a diferentes estilos de carrocería con un fuerte parecido familiar. La carrocería baja y ancha con una postura asertiva, el diseño compacto de la cabina 2+2, los voladizos mínimos y una larga distancia entre ejes encarnan las proporciones clásicas de los autos deportivos pero con una sensación claramente moderna y eléctrica.

“Este automóvil es un punto de encuentro entre la tecnología y el arte, entre la precisión y la escultura, con una postura decidida pero no agresiva”, continúa Maximilian Missoni.

La aerodinámica se manipula para maximizar el alcance gracias a características de diseño ocultas como conductos integrados que mejoran el flujo de aire laminar sobre las ruedas y los lados de la carrocería, y las luces traseras que funcionan como aspas de aire para reducir la turbulencia detrás del automóvil.

Sostenibilidad y tecnología

Polestar O2 también muestra avances en sostenibilidad y tecnología. Un nuevo monomaterial termoplástico se presenta ampliamente en el interior. El término “monomaterial” describe el uso de un solo material base para fabricar diferentes componentes.

En Polestar O2, el poliéster reciclado es el único material utilizado para todos los componentes blandos del interior: espuma, adhesivo, fibras de punto 3D y laminación no tejida. Esto simplifica el reciclaje y es un paso significativo hacia una mayor circularidad, al mismo tiempo que reduce el peso y el desperdicio.

Los equipos de sustentabilidad de Polestar creen que los materiales deben reciclarse, no reciclarse. En Polestar O2 han integrado un nuevo método para controlar el contenido reciclado y mejorar la circularidad de los componentes metálicos. Se utilizan diferentes grados de aluminio en todo el chasis para ayudar a brindar una experiencia de manejo emocionante.

Estos diferentes grados están etiquetados, lo que permite que se reciclen de manera más efectiva y que se conserven sus propiedades. El aluminio de alta calidad sigue siendo de alta calidad, mientras que otros grados mantienen sus variadas características, lo que permite una mayor eficiencia del material y un menor requerimiento de aluminio virgen.

INTERIOR El concepto Polestar O₂ prevé una nueva era para los roadster eléctricos

Innovación

En un mundo cada vez más impulsado por las redes sociales, el Polestar O2 presenta un dron cinemático autónomo integrado detrás de los asientos traseros. Desarrollado en colaboración con la marca de productos electrónicos de consumo de Aerofugia, Hoco Flow, el concepto de dron se puede implementar mientras el automóvil está en movimiento para registrar la secuencia de conducción perfecta.

Los ingenieros de Polestar han desarrollado un perfil aerodinámico especializado que se eleva detrás de los asientos traseros para crear un área tranquila de presión negativa que permite que el dron despegue cuando el automóvil está en movimiento. El dron funciona de forma autónoma, siguiendo automáticamente al coche a velocidades de hasta 90 km/h (56 mph), y el conductor puede elegir entre una secuencia atmosférica, ideal para un crucero por la costa, o una secuencia más llena de acción con una expresión más deportiva. Después de filmar, el dron puede regresar de forma autónoma al automóvil. Los videoclips se pueden editar y compartir directamente desde la pantalla central de 15 pulgadas cuando el automóvil está estacionado.

“Queríamos enfatizar la experiencia que puedes tener con un automóvil como el Polestar O2 de formas nuevas e inusuales”, continúa Maximilian Missoni. “La integración de un dron cinematográfico autónomo fue algo que nos permitió ampliar los límites en el frente de la innovación. No tener que detener y descargar el dron antes de filmar, sino desplegarlo a gran velocidad, es un beneficio clave de este diseño innovador”.

Polestar O2 continúa con los sólidos cimientos establecidos por Polestar Precept como una visión de las ambiciones futuras de diseño, tecnología y sostenibilidad de la empresa. Polestar planea lanzar tres autos nuevos en los próximos tres años, a partir de 2022, cada uno de los cuales tiene potencial para materializar gradualmente algunas de las ideas presentadas por estos autos conceptuales.

Polestar también tiene la intención de cotizar en el Nasdaq en una combinación comercial propuesta con Gores Guggenheim, Inc. (Nasdaq: GGPI, GGPIW y GGPIU), que se espera que cierre en la primera mitad de 2022.

Acerca de estrella polar

Polestar se estableció como un nuevo fabricante sueco independiente de vehículos eléctricos premium en 2017. Fundada por Volvo Cars y Geely Holding, Polestar disfruta de sinergias tecnológicas y de ingeniería específicas con Volvo Cars y, como resultado, se beneficia de importantes economías de escala.

Polestar tiene su sede en Gotemburgo, Suecia, y sus vehículos están actualmente disponibles y en circulación en los mercados de Europa, América del Norte, China y Asia Pacífico. Para 2023, la compañía planea que sus autos estén disponibles en un total de 30 mercados. Los automóviles Polestar se fabrican actualmente en dos instalaciones en China, con una fabricación futura adicional planificada en los EE. UU.

En septiembre de 2021, Polestar anunció su intención de cotizar como empresa pública en el Nasdaq en un acuerdo de combinación de negocios con Gores Guggenheim, Inc. Puede encontrar información completa sobre este acuerdo definitivo aquí .

Polestar ha producido dos autos eléctricos de alto rendimiento. El Polestar 1 se fabricó entre 2019 y 2021 como un GT híbrido de rendimiento eléctrico de bajo volumen con carrocería de fibra de carbono, 609 CV, 1000 Nm y una autonomía eléctrica de 124 km (WLTP), la más larga de cualquier coche híbrido del mundo. mundo.

El Fastback de rendimiento eléctrico Polestar 2 es el primer automóvil de alto volumen completamente eléctrico de la compañía. La gama de modelos Polestar 2 incluye tres variantes con una combinación de baterías estándar y de largo alcance de hasta 78 kWh, y sistemas de propulsión de motor único y doble con hasta 300 kW / 408 hp y 660 Nm.

En los próximos tres años, Polestar planea lanzar un nuevo vehículo eléctrico por año, comenzando con Polestar 3 en 2022, el primer SUV eléctrico de alto rendimiento de la compañía. Se espera que Polestar 4 siga en 2023, un cupé SUV de rendimiento eléctrico más pequeño.

En 2024, se planea lanzar el Polestar 5 GT de 4 puertas con rendimiento eléctrico como la evolución de producción de Polestar Precept, el auto conceptual manifiesto que Polestar lanzó en 2020 que muestra la visión futura de la marca en términos de diseño, tecnología y sostenibilidad. A medida que la compañía busca reducir su impacto climático con cada nuevo modelo, Polestar tiene como objetivo producir un automóvil verdaderamente neutral para el clima para 2030.

Acerca de Gores Guggenheim, Inc.

Gores Guggenheim, Inc. (Nasdaq: GGPI, GGPIW y GGPIU) es una empresa de adquisición de propósito especial patrocinada por una afiliada de The Gores Group, LLC, fundada por Alec Gores, y por una afiliada de Guggenheim Capital, LLC. Gores Guggenheim completó su oferta pública inicial en abril de 2021, recaudando aproximadamente USD 800 millones en efectivo con el fin de efectuar una fusión, intercambio de capital, adquisición de activos, compra de acciones, reorganización o combinación comercial similar con una o más empresas.

Declaraciones prospectivas

Ciertas declaraciones en este comunicado de prensa (“Comunicado de prensa”) pueden considerarse “declaraciones prospectivas” según se define en la Ley de Reforma de Litigios sobre Valores Privados de 1995. Las declaraciones prospectivas generalmente se relacionan con eventos futuros o el desempeño financiero u operativo futuro de Gores Guggenheim, Inc. (“Gores Guggenheim”), Polestar Performance AB y/o sus filiales (la “Compañía”) y Polestar Automotive Holding UK Limited (“ListCo”). Por ejemplo, las proyecciones de EBITDA o ingresos ajustados futuros y otras métricas son declaraciones prospectivas. En algunos casos, puede identificar declaraciones prospectivas por terminología como “puede”, “debería”, “esperar”, “pretender”, “hará”, “estimar”, “anticipar”, “creer”, “predecir” , “potencial”, “pronóstico”, “planificar”, “buscar”, “futuro”, “proponer” o “continuar”, o los negativos de estos términos o variaciones de ellos o terminología similar. Dichas declaraciones prospectivas están sujetas a riesgos, incertidumbres y otros factores que podrían causar que los resultados reales difieran materialmente de los expresados o implícitos en dichas declaraciones prospectivas.

Estas declaraciones prospectivas se basan en estimaciones y suposiciones que, si bien Gores Guggenheim y su gerencia, y la Compañía y su gerencia, según sea el caso, las consideran razonables, son intrínsecamente inciertas. Los factores que pueden causar que los resultados reales difieran materialmente de las expectativas actuales incluyen, pero no se limitan a: (1) la ocurrencia de cualquier evento, cambio u otras circunstancias que puedan dar lugar a la terminación de acuerdos definitivos con respecto a la Combinación de Negocios; (2) el resultado de cualquier procedimiento judicial que pueda iniciarse contra Gores Guggenheim, la empresa combinada u otros tras el anuncio de la Combinación de Negocios y cualquier acuerdo definitivo con respecto a la misma; (3) la imposibilidad de completar la Combinación de Negocios debido a que no se obtuvo la aprobación de los accionistas de Gores Guggenheim, para obtener financiamiento para completar la Combinación de Negocios o para satisfacer otras condiciones para el cierre; (4) cambios a la estructura propuesta de la Combinación de Negocios que puedan ser necesarios o apropiados como resultado de las leyes o regulaciones aplicables o como condición para obtener la aprobación regulatoria de la Combinación de Negocios; (5) la capacidad de cumplir con los estándares de cotización en bolsa luego de la consumación de la Combinación de Negocios; (6) el riesgo de que la Combinación de Negocios interrumpa los planes y operaciones actuales de la Compañía como resultado del anuncio y consumación de la Combinación de Negocios; (7) la capacidad de reconocer los beneficios anticipados de la Combinación de Negocios, que pueden verse afectados por, entre otras cosas, la competencia, la capacidad de la compañía combinada para crecer y administrar el crecimiento de manera rentable, mantener relaciones con clientes y proveedores y retener a su gerencia y empleados clave; (8) costos relacionados con la Combinación de Negocios; (9) riesgos asociados con cambios en las leyes o reglamentos aplicables y las operaciones internacionales de la Compañía; (10) la posibilidad de que la Compañía o la compañía combinada se vea afectada negativamente por otros factores económicos, comerciales y/o competitivos; (11) las estimaciones de gastos y rentabilidad de la Compañía; (12) la capacidad de la Compañía para mantener acuerdos o asociaciones con sus socios estratégicos Volvo Cars y Geely y para desarrollar nuevos acuerdos o asociaciones; (13) la capacidad de la Compañía para mantener relaciones con sus proveedores y socios estratégicos existentes, y buscar nuevos proveedores para sus componentes críticos, y para completar la construcción de su cadena de suministro, mientras gestiona de manera efectiva los riesgos debido a tales relaciones; (14) la confianza de la Compañía en sus asociaciones con redes de carga de vehículos para proporcionar soluciones de carga para sus vehículos y sus socios estratégicos para dar servicio a sus vehículos y su software integrado; (15) la capacidad de la Compañía para establecer su marca y capturar una participación de mercado adicional, y los riesgos asociados con la prensa negativa o el daño a la reputación, incluso cuando las celdas de las baterías de iones de litio se incendian o expulsan humo; (16) demoras en el diseño, fabricación, lanzamiento y financiamiento de los vehículos de la Compañía y la dependencia de la Compañía de un número limitado de modelos de vehículos para generar ingresos; (17) la capacidad de la Compañía para innovar continua y rápidamente, desarrollar y comercializar nuevos productos; (18) riesgos relacionados con la futura adopción en el mercado de las ofertas de la Compañía; (19) aumentos en los costos, interrupción del suministro o escasez de materiales, en particular para celdas de iones de litio o semiconductores; (20) la confianza de la Compañía en sus socios para fabricar vehículos a gran escala, algunos de los cuales tienen experiencia limitada en la producción de vehículos eléctricos, y en la asignación de capacidad de producción suficiente a la Compañía por parte de sus socios para que la Compañía pueda aumentar sus capacidades de producción de vehículos; (21) riesgos relacionados con el modelo de distribución de la Compañía; (22) los efectos de la competencia y las altas barreras de entrada en la industria automotriz, y el ritmo y la profundidad de la adopción de vehículos eléctricos en general en el negocio futuro de la Compañía; (23) cambios en los requisitos reglamentarios, incentivos gubernamentales y precios de combustibles y energía; (24) el impacto de la pandemia global de COVID-19 en Gores Guggenheim, la Compañía, los resultados de operaciones proyectados posteriores a la combinación comercial de la Compañía, el desempeño financiero u otras métricas financieras, o en cualquiera de los riesgos anteriores; y (25) otros riesgos e incertidumbres establecidos en la sección titulada “Factores de riesgo” y “Nota de advertencia sobre declaraciones prospectivas” en el prospecto final de Gores Guggenheim en relación con su oferta pública inicial (Archivo No. 333-253338) declarado efectivo por la SEC el 22 de marzo de 2021, y otros documentos presentados o que se presentarán ante la SEC por Gores Guggenheim o ListCo, incluida la Declaración de registro/poder. Puede haber riesgos adicionales que ni Gores Guggenheim, la Compañía ni ListCo conocen actualmente o que Gores Guggenheim,

Nada en este comunicado de prensa debe considerarse como una representación por parte de ninguna persona de que se lograrán las declaraciones prospectivas establecidas en este documento o que se logrará cualquiera de los resultados contemplados en dichas declaraciones prospectivas. No debe depositar una confianza indebida en las declaraciones prospectivas, que se refieren solo a la fecha en que se realizan. Ni Gores Guggenheim, la Compañía ni ListCo asumen ninguna obligación de actualizar estas declaraciones prospectivas.

información adicional

En relación con la Combinación de Negocios propuesta, (i) ListCo ha presentado ante la SEC una Declaración de Registro/Apoderado, y (ii) Gores Guggenheim presentará una declaración de poder definitiva relacionada con la Combinación de Negocios propuesta (la “Declaración de Poder Definitiva”) y enviará por correo la Declaración de Poder Definitiva y otros materiales relevantes a sus accionistas después de que el Registro/Declaración de Poder sea declarado efectivo. La Declaración de Registro/Apoderado contendrá información importante sobre la Combinación de Negocios propuesta y los otros asuntos que se someterán a votación en una reunión de accionistas de Gores Guggenheim que se llevará a cabo para aprobar la Combinación de Negocios propuesta. Este comunicado de prensa no contiene toda la información que debe considerarse en relación con la Combinación de negocios propuesta y no pretende constituir la base de ninguna decisión de inversión ni ninguna otra decisión con respecto a la Combinación de negocios. Antes de tomar decisiones de votación u otras decisiones de inversión, se recomienda a los tenedores de valores de Gores Guggenheim y otras personas interesadas que lean la Declaración de registro/poder y las enmiendas a la misma y la Declaración de poder definitiva y otros documentos presentados en relación con la Combinación comercial propuesta, ya que estos Los materiales contendrán información importante sobre Gores Guggenheim, la empresa, ListCo y la combinación comercial. Cuando esté disponible, la Declaración de Poder Definitiva y otros materiales relevantes para la Combinación de Negocios propuesta se enviarán por correo a los accionistas de Gores Guggenheim a partir de una fecha de registro que se establecerá para votar sobre la Combinación de Negocios propuesta. Los accionistas también podrán obtener copias de la Declaración de registro/poder, la Declaración de poder definitiva y otros documentos presentados ante la SEC, sin cargo, una vez que estén disponibles, en el sitio web de la SEC enwww . segundo _ gov , o dirigiendo una solicitud a: Gores Guggenheim, Inc., 6260 Lookout Rd., Boulder, CO 80301, atención: Jennifer Kwon Chou.

LA INVERSIÓN EN CUALQUIERA DE LOS VALORES DESCRITOS EN EL PRESENTE DOCUMENTO NO HA SIDO APROBADA O DESAPROBADA POR LA SEC O CUALQUIER OTRA AUTORIDAD REGULADORA NI HA APROBADO O RESPALDADO NINGUNA AUTORIDAD LOS MÉRITOS DE LA OFERTA O LA EXACTITUD O ADECUACIÓN DE LA INFORMACIÓN CONTENIDA EN EL PRESENTE DOCUMENTO. CUALQUIER DECLARACIÓN EN CONTRARIO ES UN DELITO PENAL.

Participantes en la Solicitud

Gores Guggenheim y algunos de sus directores y funcionarios ejecutivos pueden considerarse participantes en la solicitud de poderes de los accionistas de Gores Guggenheim con respecto a la Combinación de negocios propuesta. Una lista de los nombres de esos directores y funcionarios ejecutivos y una descripción de sus intereses en Gores Guggenheim se establece en las presentaciones de Gores Guggenheim ante la SEC (incluido el prospecto final de Gores Guggenheim relacionado con su oferta pública inicial (Archivo No. 333-253338) declarado efectivo por la SEC el 22 de marzo de 2021), y están disponibles de forma gratuita en el sitio web de la SEC en www . segundo _ gobierno, o dirigiendo una solicitud a Gores Guggenheim, Inc., 6260 Lookout Rd., Boulder, CO 80301, atención: Jennifer Kwon Chou. La información adicional sobre los intereses de dichos participantes se encuentra en la Declaración de registro/representación.

La Compañía y ListCo, y algunos de sus directores y funcionarios ejecutivos también pueden considerarse participantes en la solicitud de poderes de los accionistas de Gores Guggenheim en relación con la combinación de negocios propuesta. En la Declaración de Registro/Apoderado se incluye una lista de los nombres de dichos directores y funcionarios ejecutivos e información sobre sus intereses en la Combinación de Negocios propuesta.

Sin oferta y sin solicitud

Este comunicado de prensa no es una declaración de poder ni una solicitud de poder, consentimiento o autorización con respecto a ningún valor o con respecto a la transacción potencial y no constituirá una oferta de venta o una solicitud de una oferta de compra de valores de Gores Guggenheim. , la Compañía o ListCo, ni habrá ninguna venta de dichos valores en ningún estado o jurisdicción en la que dicha oferta, solicitud o venta sea ilegal antes del registro o calificación según las leyes de valores de dicho estado o jurisdicción. No se realizará ninguna oferta de valores excepto por medio de un prospecto que cumpla con los requisitos de la Ley de Valores de 1933, enmendada.