The road trip reinvented with a new technological model for series production

Stuttgart. Range and efficiency are set to define the electric age. Exceptional range will make electric cars suitable for every journey and accelerate their adoption. The exceptional efficiency will create a virtuous cycle of reducing battery size and weight, allowing us to go further with less. Mercedes-Benz is determined to lead the way. We already lead the real range charts with the 245 kW EQS (WLTP combined electricity consumption: 19.8-15.7 kWh/100 km; CO2 emissions: 0 g/km)[1], as shown by the recent test of Edmunds where an EQS 450+ traveled 422 miles on a single charge, 77 miles more than any other car previously tested.

The VISION EQXX displays

But Mercedes-Benz does not rest. Driven by the idea of zero impact on our planet and highly responsible use of green energy, we inspire our engineers to go further. They are working hard to take range and efficiency to a whole new level. The VISION EQXX is the result of a mission we set out to break down technological barriers across the board and take energy efficiency to new heights. It demonstrates the gains that are possible by rethinking fundamentals from scratch. This includes advances in all elements of its state-of-the-art electric drivetrain, as well as the use of lightweight engineering and sustainable materials. Complete with a host of innovative and smart efficiency measures, including advanced software,

“The Mercedes-Benz VISION EQXX is how we envision the future of electric cars. Just a year and a half ago, we started this project that led to the most efficient Mercedes-Benz ever built, with an outstanding energy consumption of less than 10 kWh per 100 kilometers. It has a range of more than 1,000 kilometers[2] on a single charge using a battery that would fit even in a compact vehicle. The VISION EQXX is an advanced car in many dimensions, and it even looks impressive and futuristic. With that, he underscores where our entire company is headed: we will build the most desirable electric cars in the world.” Ola Källenius, Chairman of the Board of Management of Daimler AG and Mercedes-Benz AG

VISION EQXX : designed for the road trip to electromobility

There’s a reason road trips have been a cultural touchstone for at least 70 years, telling stories of the road in books, movies, and music. The road trip defines freedom, individuality, the very spirit of the automobile and of the passing world. Stick a pin in the map and drive. Be in tune with the asphalt and with the car. This drive to explore, discover and delight in the world beyond our horizon is part of what it is to be human. It is the pioneering spirit that unites the vision with the tenacity to make it happen.

The journey to electric mobility is a road trip; as exciting as it is challenging, as unknown as it is safe. The Mercedes-Benz VISION EQXX is a vehicle designed for that road trip. It responds to the progressive demands of a modern generation of customers and emotionality through innovation. As part of a far-reaching technology program, this software-defined research prototype was designed by women and men with the creativity, ingenuity and determination to deliver one of the most efficient cars on the planet, in every way. They did it using the latest digital technology, the agility of a start-up and the speed of Formula 1.

The result is a masterpiece of efficiency that, based on internal digital simulations in real traffic conditions, will be capable of exceeding 1,000 kilometers [3] on a single charge with exceptional energy consumption of less than 10 kWh per 100 kilometers ( efficiency of more than 6 miles per kWh).

Breaking the automotive engineering rulebook, Mercedes-Benz has built a software-driven electric car that reimagines road travel for the electric age. At the same time, it presents a highly progressive interpretation of the fundamental Mercedes-Benz principles of modern luxury and sensual purity. Instead of simply increasing battery size, the cross-functional international team focused on maximizing long-distance efficiency. They pulled out all the stops in powertrain efficiency, energy density, aerodynamics, and lightweight design.

“The technology program behind VISION EQXXit will define and enable future Mercedes-Benz models and features,” says Markus Schäfer, Member of the Board of Management of Daimler AG and Mercedes-Benz AG, Chief Technology Officer responsible for Development and Acquisitions. “As a halo car, the VISION EQXX firmly establishes Mercedes-Benz as the brand that combines luxury with technology in the automotive world and beyond. And the way we develop it is as revolutionary as the vehicle itself. VISION EQXX has seen the best minds from our R&D centers work together with engineers from our Formula 1 and Formula E programmes. They are proving that motorsport innovations, where powertrains are already highly electrified, have relevance. immediate for the development of road cars.

The VISION EQXX is an exciting, inspiring and completely realistic path to electric vehicle technology. In addition to its revolutionary energy efficiency, it offers significant answers to pressing problems. For example, sustainable materials considerably reduce the carbon footprint. Its UI/UX features a radical new one-piece display that comes to life with real-time responsive graphics and spans the full width of the vehicle. Other UI/UX elements help the car and driver work together as one, and even use technology that mimics how the human brain works. And the software-driven development process that delivered it revolutionizes the way electric cars are designed.

This car is one of the results of an ongoing program that is delivering a blueprint for the future of automotive engineering. Many of its features and developments are already being integrated into production, including the next generation of MMA: Mercedes-Benz’s modular architecture for compact and midsize cars.

The VISION EQXX shows how Mercedes-Benz envisions the future of electric cars.

The VISION EQXX is how Mercedes-Benz envisions the future of electric cars.

VISION EQXX: main points at a glance

A car with a mission: the most efficient Mercedes-Benz ever built

Efficiency means achieving more with less. The VISION EQXX is packed with efficiency improvements that push the limits with a combination of advanced technology and talented teamwork. The result will be a road-legal research prototype that offers more range with less power, more tangible luxury and comfort with less impact on nature, and more electric mobility with less waste. A host of digital tools and a software-based approach have also delivered more cars in less time.

#EnergyWizard: Overall, efficiency engineering achievements resulted in staggering energy consumption of less than 10 kWh per 100 km (efficiency of more than 6 miles per kWh)

#ElectricDrive: radical new system designed and built in-house – achieves 95% baseline efficiency from battery to wheels

#RangeBuster: 1000+ km (620+ miles)[4] on a single charge on public roads puts an end to range anxiety

#EnergyDensity: With expert engineering and Formula 1 thinking, our battery chemists squeezed the energy of the EQS into the dimensions of a compact car. The VISION EQXX battery pack packs nearly 100 kWh of energy, but is 50% less volume and 30% lighter than the EQS reference pack.

#AeroChamp: Exterior designers and aerodynamicists achieved a reference coefficient of drag of 0.17 cd[5]

#SustainableMaterials: Innovative plant-based and recycled materials eliminate waste from landfills and reduce carbon footprint

#UpliftMindset: A pioneering team of Mercedes-Benz engineers worked with the world’s fastest racing lab on High Performance Powertrains (HPP) and Mercedes-Benz Grand Prix (MGP) to design a highly efficient and compact electric drivetrain and a lightweight battery box

#BionicEngineering: Inspired by natural forms and in partnership with innovative startups, engineers used advanced digital tools to reduce weight and reduce waste by removing excess material with the help of 3D printing.

#RollingEfficiency: Ultra-low rolling resistance tires with optimized aerodynamic geometry are combined with lightweight magnesium wheels for increased range

#BrakingLightly: Lightweight brake discs made of aluminum alloy fit the VISION EQXX perfectly and help keep the weight down

#EfficiencyOnTheRoad: F1’s lightweight subframe electric-only chassis brings racing efficiency to the road

#SolarPower: ultra-thin roof panels power the battery system for up to 25km of extra range

#HumanMachineMerge: Intuitive and intelligent user interface and user experience with guidance and assistance for efficient driving brings harmony even closer to the electric age

#SensualPurity: EV’s fully focused exterior/interior design ethic underscores role as a halo car for the all-electric future. Mercedes-Benz will make the most desirable cars

#FastTechProg: From a clean sheet to being on the road in just 18 months. The VISION EQXX is part of a technology program that can bring innovative technologies to series production faster than ever.

#Transformation: VISION EQXX demonstrates the transformation of Mercedes-Benz into an all-electric, software-driven company

#SoftwareDriven: Software-based approach key to success in achieving efficiency goals and a rapid development process, including an innovative battery management system.

#GlobalResponsibleLeadership: VISION EQXX accelerates Mercedes-Benz’s goal to “Lead in Electricity” and set benchmarks in sustainable mobility.

The VISION EQXX shows how Mercedes-Benz envisions the future of electric cars.

The VISION EQXX is how Mercedes-Benz envisions the future of electric cars.

VISION EQXX: key technical data at a glance[6]

| Battery energy content, usable |

kWh |

<100 |

| max. system voltage |

volts |

>900 |

| Energy consumption |

kWh/100 km (miles/kWh) |

<10(>6) |

| dc value |

|

0.17 [7] |

| max. power output |

kilowatts |

~150 |

| distance between axis |

cm |

280 |

| gross vehicle weight |

kg |

~1,750 |

Efficiency is the new currency

In essence, efficiency means achieving more with less. This is nothing new: Mercedes-Benz has always strived for efficiency in its vehicles, making massive technological advances over the decades. These have benefited consumers through consistent improvements in fuel economy, comfort and convenience. However, the imperatives of electric mobility and sustainability have changed the framework for efficiency.

The most familiar expression of automotive efficiency is that of fuel consumption or fuel economy. This is expressed in different ways depending on where you are in the world (for example, liters per 100 kilometers, miles per gallon, or kilometers per liter). Regardless of convention, they all relate units of fuel (energy) to units of distance. Electric mobility is no different in that regard.

By making efficiency the new currency, Mercedes-Benz has created a common denominator to quantify technological development across the board, beyond fuel efficiency. As well as meaning more range with less power, it also means more tangible luxury and comfort with less impact on nature and more electric mobility with less waste.

The VISION EQXX proves that all of this is within easy reach in a real-world vehicle that pushes limits on every front. It gives Mercedes-Benz customers a clear view of what premium efficiency for the electric and digital age looks and feels like. Beautiful design and intuitive operation enhanced by advanced digital technologies deliver sustainable long-distance electric mobility that has Mercedes-Benz written all over it.

“The suffix XX augments the Mercedes-Benz brand with the X-factor of electric mobility that thinks beyond limitations and an agile collaborative development approach from the X division,” explains Markus Schäfer, continuing: “This enhances the breadth and depth of development. skills within Mercedes-Benz AG with highly advanced digital tools, as well as industry-leading expertise from a wide range of partner companies, start-ups and institutions around the world.”

From its innovative powertrain to its lightweight “bionic” structure, and from its ingenious thermal management to its serenely slick exterior, efficiency engineering in every detail adds to the VISION EQXX’s remarkable power consumption and true range.

“Electric cooking sounds easy, but it is a complex technical challenge. The easiest way is to put a larger battery in the car. However, this leads to diminishing returns due to size and weight. This is definitely not the smartest route and it’s also not the best use of scarce resources. With VISION EQXX, we present the results of an extraordinary challenge: we take efficiency to a whole new level. And we explore new ways to increase the range of an electric car.” Joerg Bartels, Vice President of Vehicle Engineering and General Vehicle Functions.

This remarkable project went from white paper to full vehicle in just 18 months. He attracted talent not only from Stuttgart, but also from Formula 1 and from a diverse range of start-ups, partners and institutions from around the world in a cross-functional and multi-disciplinary team. Facing each other, they applied the latest technologies and ideas to develop advanced, high-efficiency solutions with real potential for the near future.

The VISION EQXX shows how Mercedes-Benz envisions the future of electric cars.

The VISION EQXX is how Mercedes-Benz envisions the future of electric cars.

Pioneer transmission for the electric age: don’t waste, don’t want

On any road trip, it’s the car that does the work, soaking up the miles and letting the driver and passengers experience the journey. In the long-distance mindset that makes the VISION EQXX so special, efficiency is king.

Producing around 150kW, the super-efficient electric drivetrain (encompassing everything from the battery to the electric drive unit to the wheels) in the VISION EQXX provides the power and toughness to sustain this exceptional long-distance runner. distance. More than a composition of individual parts, it is an engineering work of art in its own right. Tasked with a very clear and specific set of goals, the team set out to create an electric powertrain with a world-leading combination of efficiency, energy density and lightweight engineering. So let’s add a figure here: 95% efficiency. That means up to 95% of the battery’s energy ends up in the wheels, pure and simple.

The Formula 1 experts at Mercedes-AMG High Performance Powertrains (HPP) in Brixworth, UK know a thing or two about how to harness every kilojoule of energy. In close collaboration, Mercedes-Benz R&D worked hand-in-hand with them to redesign the powertrain and reduce system losses.

“One of the best ways to improve efficiency is to reduce losses,” explains Eva Greiner, chief engineer of the electric drive system at Mercedes-Benz. “We work on every part of the system to reduce energy consumption and losses through system design, material selection, lubrication and heat management. And our fantastic simulation tools helped us quickly figure out what works and what doesn’t.”

The electric drive unit of the VISION EQXX is a dedicated unit consisting of the electric motor, transmission and power electronics with a new generation of silicon carbide. The power electronics unit is based on that of the upcoming Mercedes-AMG Project ONE hypercar.

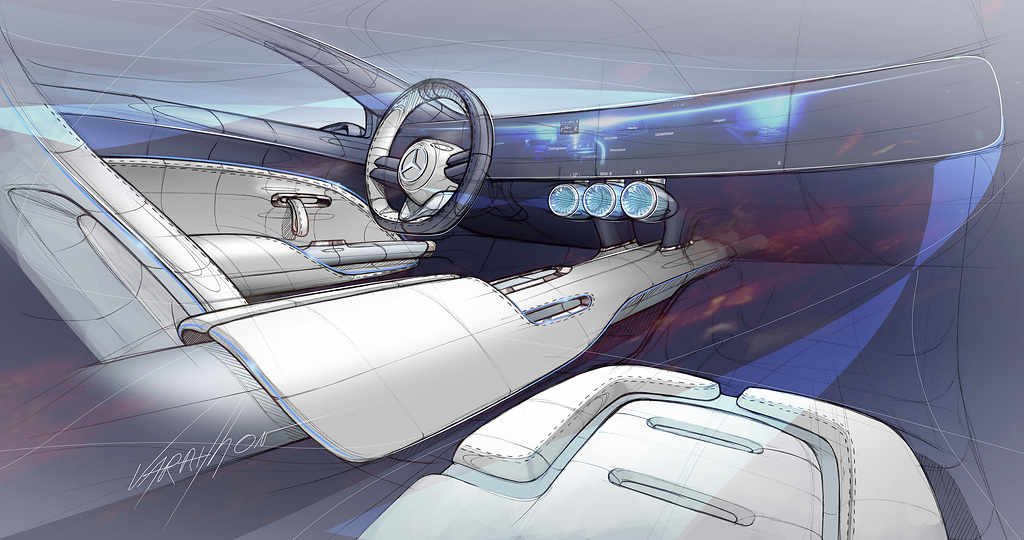

Mercedes-Benz VISION EQXX

, interior Mercedes-Benz VISION EQXX, interior

The best in battery development in collaboration with HPP

Instead of simply increasing the size of the battery, Mercedes-Benz and the HPP team developed an entirely new battery pack for the VISION EQXX, achieving a remarkable energy density of close to 400 Wh/l. This benchmark figure is what made it possible to fit a battery pack with just under 100 kWh of usable energy into the compact dimensions of the VISION EQXX.

“In effect, we matched the power of the EQS to the vehicle dimensions of a compact car,” says Adam Allsopp, director of advanced technology at HPP. “The battery has about the same amount of power but is half the size and 30% lighter. The battery management system and power electronics have been designed with an absolute focus on loss reduction. By achieving this efficiency milestone, we learned a lot that will flow into future development programs.”

The substantial increase in energy density stems in part from significant progress in anode chemistry. Their higher silicon content and advanced composition mean they can hold much more energy than commonly used anodes. Another feature that contributed to the impressive power density is the high level of integration in the battery pack. This platform, jointly developed by Mercedes-Benz R&D and HPP, created more space for the cells and helped reduce overall weight. The separate compartment for electrical and electronic (EE) components, called the OneBox, also made more space for the cells, with added benefits for installation and removal.

Tasked with pushing the limits of technical feasibility at every level, the battery development team also decided to experiment with unusually high voltage. Increasing the voltage to over 900 volts proved to be an extremely useful research tool for power electronics development. The team was able to collect a lot of valuable data and is currently evaluating the potential benefits and implications for future series production.

Several more aspects of the battery’s design add to its exceptional efficiency. For example, its lightweight lid was jointly designed by Mercedes-AMG HPP and its chassis partners at Mercedes-Grand Prix. The lid is made from a unique and sustainable composite material derived from sugar cane waste, reinforced with carbon fibre, as used in Formula 1. The battery also features active cell balancing, which means extracting the power evenly from the cells while the car is running. conduction, in effect, giving it greater resistance. In general, the battery weighs around 495 kilograms, including the OneBox.

Taking the heat: the innovative thermal management system

Those who paid attention in physics class will know that heat is a form of energy in a new guise. It can be your enemy or your friend. The VISION EQXX has an advanced thermal management system. On the one hand, it conserves thermal energy, and on the other, it significantly reduces cooling resistance. Both contribute to maximum efficiency.

How? Mercedes-Benz’s “cooling on demand” concept has been further developed for the VISION EQXX not only for optimal cooling depending on prevailing circumstances. The exceptional efficiency of the electric drive unit means it generates only minimal waste heat. This helped keep the thermal management system extremely small and light. The carefully designed interplay of airfoil shutters, coolant valves and water pumps ensures that the electric drive unit, comprising power electronics, electric motor and transmission, maintains the most cost-efficient temperature balance. minimum energy. Technically,

The cooling plate is installed in the floor of the vehicle, allowing you to take advantage of the air that flows along the bottom of the VISION EQXX. This is the most aerodynamically efficient way of keeping the electric drive unit cool under normal conditions, allowing the vehicle to gain around 20 kilometers of range in the most aerodynamic mode.

Only when it is hot or the driving style is “lively”, the cooling system increases a little. Normally closed louvers at the front of the VISION EQXX open when things get hot, sending additional cooling air through a system of air guides. The inlets for these air guides are cleverly located along the highest pressure area of the front bumper. Rather, the outlets are in low-pressure zones along the top of the hood.

The beauty of this “cooling on demand” approach is that when the shutters are open, it adds just seven points (0.007) to the drag coefficient. If cooling is required when the vehicle is stationary, a backup cooling fan is activated (thermal efficiency mode).

Mercedes-Benz VISION EQXX

, interior Mercedes-Benz VISION EQXX, interior

Keeping the heat: a heat pump makes the most of ambient and waste heat

The VISION EQXX’s innovative heat pump absorbs heat generated by the drivetrain and outside ambient air to keep the cabin cozy. Its impressive efficiency is a huge boost for battery life in the coldest parts of the world.

This multi-source heat pump recovers waste heat from the powertrain and has an external heat exchanger that extracts heat from the ambient air. Not available on earlier Mercedes-Benz heat pumps, this feature increases the operating temperature range. This is especially useful for quickly heating up the cabin and is very effective at lower temperatures. And to squeeze out every last calorie of heat, it even uses “evaporator enthalpy” when dehumidifying humid room air. Enthalpy is the latent energy released as heat when water vapor in the air changes state from gas to water.

Let the sun in: more range thanks to solar energy

The sun is the original source of all energy on Earth, but it can take a very crooked path. So it made perfect sense for Mercedes-Benz development engineers to cut out the “middle man” and go straight to the big boiler in the sky for a little extra oomph.

The electrical system that powers many of the VISION EQXX’s accessories draws additional power from 117 solar cells on the roof. It was developed in collaboration with the Fraunhofer Institute for Solar Energy Systems ISE, the largest solar energy research institute in Europe. The net result of reducing power consumption on the high voltage system is an increase in range. In a single day and under ideal conditions, this can add up to 25 km of range on long-distance trips.

Solar energy is stored in a lightweight lithium iron phosphate battery, which powers a climate fan, lights, infotainment system and other accessories. Mercedes-Benz and its partners are working to use solar energy to charge the high-voltage system as well.

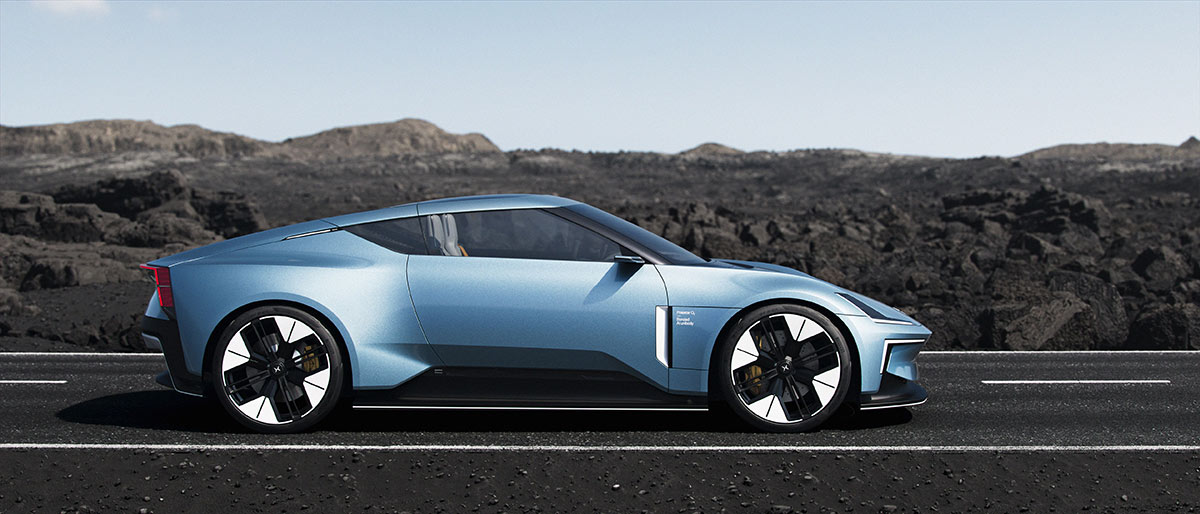

Design and aerodynamics: a master class in conflict resolution

Over long distances on the open road, one of the biggest obstacles to efficiency is staring us in the face, but we can’t see it. The air may be fresh and inviting, but it wants to hold us in its hands. Aerodynamic drag can have a big impact on range. On a regular long-distance trip, a typical electric vehicle devotes almost two-thirds of its battery capacity to making its way through the air, which is why the VISON EQXX has an ultra-slick and slippery coefficient of drag of 0.17[8] .

However, the disciplines of aerodynamics and design often have opposing interests, as Gorden Wagener, Head of Design at Daimler AG and Mercedes-Benz AG, explains: „The VISION EQXX is a vision of the future that embodies the desire for the next mercedes level of luxury As designers, we always think in terms of technology and aesthetics. The aerodynamics of the VISION EQXX embodies this fusion of technology and aesthetics for us as designers. In line with our philosophy of Sensual Purity, we create spectacular proportions that combine beauty with efficiency. The resulting body flow offers revolutionary aerodynamics. The fact that the end result is as beautiful as it is demonstrates the skill of our design team working closely with aerodynamics experts.”

The Mercedes-Benz team has a long tradition of working closely together to achieve striking design with class-leading aerodynamics, from the W 125[9] in 1937 and the 540K Streamliner of 1938 to the Concept C111[10] from the 1970s to the current RCT. Another excellent example is the IAA Concept from 2015[11], which provided significant inspiration for the VISION EQXX. It was, for example, the first Mercedes-Benz vehicle to make extensive use of active aerodynamic features to achieve notable improvements in drag coefficient combined with the distinctively elegant lines of Mercedes-Benz design.

A great deal of work went into integrating the painstaking passive and active aerodynamic features into the external shape of the VISION EQXX. The remarkable result was achieved in an impressively short time. The interdisciplinary team used advanced digital modeling techniques to arrive at a compromise that reduces drag while retaining the sensuous purity of the Mercedes-Benz design language and the practicalities of a road car.

“Usually it takes about a year to finalize the form,” says Mercedes-Benz aerodynamics chief Teddy Woll. “We had less than half of that for VISION EQXX. Lean and agile processes and mature digital tools make collaborative work much easier, with faster decision-making and more agile engagements. We also needed fewer models and less time in the wind tunnel.”

Despite the practical challenges and compressed time scale, the success of the collaboration is clearly evident in the sophistication and balance of the exterior design. The surfaces of the VISION EQXX run smoothly from the front, developing powerful yet sensuous shoulders above the rear wheel arches. This natural flow is concluded with a clearly defined, aerodynamically effective tear-off edge, accentuated by gloss black trim, highlighted by the taillight clusters.

Painted in a striking silver Mercedes-Benz Alubeam look, the body of the VISION EQXX cradles the smooth greenhouse dome as it flows gracefully like a drop of water to the rear. The retractable rear diffuser is a powerful example of the collaboration between design, aerodynamics and engineering: it deploys only at higher speeds when the air becomes a considerably tougher opponent. When retracted, it fits seamlessly into the bodywork, retaining the balance, proportions and lightweight aesthetics of the rear.

However, it presented a significant engineering challenge. Standing face to face with the laws of physics, the development engineers working on it had to ensure that this seemingly simple mechanism met a number of requirements. In addition to operating in all conditions, it also had to weigh next to nothing and retract instantly in the event of a rear-end collision.

The VISION EQXX has a number of less visually obvious but equally important active and passive aerodynamic details, such as its small frontal area. In fact, it is less than that of the current CLA or even that of smart vehicles. And how many would notice that the rear track is 50 millimeters shorter than the front? Another is the air curtain/air vent in the front bumper. This clever design combines with the wheel covers to eliminate almost every last murmur of aerodynamic separation from the front wheels. And while all that’s going on, the airways even guide additional cooling air over the hood, opening the cooling louvers if necessary.

Despite its small frontal area, the front end of the VISION EQXX packs a big design punch. A band of light above the gloss black grille with rose gold accents flows effortlessly into the fuel-efficient headlamps, reminiscent of those on the EQS. Each headlight consists of two star-shaped elements, the larger housing the low beam and low beam assemblies behind a bright central lens. This arrangement, along with the 2D star pattern on the front bumper, provides a preview of the front-end design details that will be featured on future Mercedes-Benz models.

Mercedes-Benz VISION EQXX, Design, Skizze, Interieur

Mercedes-Benz VISION EQXX, design sketch interior

Efficient wheels and tires – optimized for rolling resistance and aerodynamics

In all cars, it is the tires that form the most important interface with the road. For the VISION EQXX, Mercedes-Benz engineers worked in cooperation with Bridgestone. Together, they harnessed Bridgestone’s Turanza Eco tire combined with lightweight, environmentally friendly ENLITEN and ologic technology that enables ultra-low rolling resistance.

The tire design also features aerodynamically optimized sidewalls to match the casings mounted on the lightweight 20-inch forged magnesium wheels. The semi-transparent, twin-spoke design of these covers meets all aerodynamic requirements while preserving the view of the rose gold accents that adorn the wheels.

The beautiful simplicity of light interior design

Marking the launch of a new super purist design style, VISION EQXX represents a new expression of efficiency in interior design. Moving away from the conventional design approach, the interior design focuses on a few modules and the beautiful simplicity of lightweight design. This is expressed through the absence of complex shapes and the integration of light structures into the interior aesthetics in a totally organic way, making traditional trim elements superfluous.

From mushrooms to vegan silk, nature’s influence continues as we step into the VISION EQXX. The light luxury feel of the interior comes from the extensive use of lightweight, sustainable materials and organically inspired design details. The basic principle is maximum comfort and style with minimum weight, and absolutely no products derived from animals.

The interior features a host of innovative materials sourced from startups around the world. For example, the door handles are made from AMsilk’s Biosteel® fiber. This vegan-certified, biotech-based, high-strength silk-like fabric comes from the inventor of bio-manufactured (nature-identical) fiber. Combining groundbreaking science with true environmental integrity, its use here marks an automotive industry first.

Another sustainable material that adorns the interior of the VISION EQXX is MyloTM, a verified vegan leather alternative made from mycelium, which is the underground root-like structure of fungi. It is certified biobased, meaning it is made predominantly from renewable ingredients found in nature. This entirely new category of material created by the power of biotechnology is designed to be less harmful to the environment and is used for the seat cushion details on the VISION EQXX.

The animal-free leather alternative called Deserttex® is a sustainable cactus-based biomaterial made from powdered cactus fibers combined with a sustainable bio-based polyurethane matrix. In this combination, the leather alternative has an exceptionally supple finish that is extremely soft to the touch. Future versions have a higher cactus content, giving this material the potential to halve the ecological footprint associated with conventional artificial leathers.

On the floor, the VISION EQXX carpets are made from 100% bamboo fiber. As well as being renewable and fast growing, this natural raw material offers an extremely luxurious look and feel. Mercedes-Benz chose these sustainable, innovative, high-performance materials because they and others like them have the potential to replace all kinds of petroleum and animal products currently used in automotive applications. Together, they show a way forward for luxury design that conserves resources and is in balance with nature.

Elsewhere, the VISION EQXX makes extensive use of recycled waste materials, such as recycled PET bottles used in a shiny fabric to enhance the floor area and door trim. Higher up in the interior, the designers used DINAMICA® made from 38% recycled PET to create a wrap-around effect that joins the top edge of the one-piece screen with the doors and headliner. The interior also features UBQ material, a sustainable plastic substitute made from household waste and municipal landfills.

“Working with these innovative and sustainable materials to design the interior of the VISION EQXX was a hugely liberating and exciting experience,” says Gorden Wagener. “They open up entirely new avenues of creativity, and the visual and tactile finishes are exquisite. The luxurious feel of the interior through the use of ambient lighting as well as silver, rose gold and gloss black accents is a very progressive interpretation of modern luxury for the all-electric age.”

The VISION EQXX UI/UX shows the potential of game engine-based interfaces, with outstanding graphics and highly responsive design.

The UI/UX in VISION EQXX showcases the potential of game engine-driven interfaces, with never-before-seen graphics and highly responsive design.

Body in white: smart, efficient and sustainable through bionic engineering and advanced materials

When it comes to light engineering, the best thing on Earth is Mother Nature. No one else comes close. Over millions of years, it has perfected the best examples of highly efficient long-distance travelers, from the monarch butterfly to the arctic tern.

With a considerably shorter timescale for the VISION EQXX, Mercedes-Benz engineers drew inspiration from their creations and enlisted some lateral-thinking outside experts to help. The result is a weight efficient design derived from engineering excellence coupled with a sustainable mix of trash and tinsel.

This clever use of nature-inspired advanced sustainable materials and methods is called bionic engineering and was facilitated by a digital process called bionic mesh design. Mercedes-Benz has a long history of applying bionic engineering techniques dating back to its 2005 “bionic car” concept study.

BIONEQXXTM Foundry

Currently Mercedes-Benz’s largest aluminum structural casting, BIONEQXX is the main structural component at the rear of the VISION EQXX: the rear floor. It was developed in-house by Mercedes-Benz using fully digital techniques and a software approach that is absolutely unique within the automotive sector. The result is optimal functionality packed within the compact dimensions of the available space. Furthermore, the team created this impressive and manufacturable casting in just four months.

Taking organic forms as a reference, the development engineers sought to use material only where it was necessary for the structural function, that is, where loads are exerted. According to the laws of nature, where there is no charge there is no need for material.

The most important of the structural criteria is the need for very high stiffness and excellent crash performance. The beauty of the one-part BIONEQXX casting is the ability to combine it with functional integration within a single extremely lightweight component rather than an assembly of several joined parts.

Bionic simulation with a touch of Hollywood magic

So how did they accomplish this in such a short amount of time? By applying a fully digital vertical process that provides a blueprint for the future development of production vehicles. In addition to classic optimization techniques, the team also applied a unique collaboration model that included graphics and polygonal modeling tools used in the 3D gaming industry and Hollywood animation.

Used by Mercedes-Benz engineers in the automotive context, these tools help identify stresses and load paths in a component. All of this happens digitally, before anything is cast in metal, greatly speeding up the development process and making it possible to create a bionic layer structure in twice as fast time.

The resulting one-piece casting has a spiderweb-like appearance with gaps where there is no need for structural elements. However, the rear floor of a vehicle is subjected to more than just physical loads in everyday use. It has to withstand nature’s attempts to enter the car in the form of water and dirt. To address this, Mercedes-Benz engineers once again turned to external partner UBQ Materials. The sustainable plastic substitute developed by the Israel-based startup is made from the kind of waste that normally ends up in landfills. This includes food and yard waste, as well as mixed plastics, cardboard, and even baby diapers. One kilogram of UBQ removes 1.3 kilograms of garbage from the landfill, of which about 0.3 kilogram is water.

The cooperation between Mercedes and UBQ won the Automotive Sustainability Award 2021 in the category of “best start-up”[12]. UBQ is not only suitable for prototype applications, but also offers great potential for transfer to series production in the near future.

The openings in the BIONEQXX rear floor mold were closed with patches made of UBQ produced on a 3D printer. A total of 42 UBQ heads were designed using shape optimization to achieve extremely high stiffness and good sound damping qualities. Once inserted into the BIONEQXX casting using a special bonding process, the final unit is completely sealed against the ravages of water and dirt. The resulting part indicates that this innovative engineering approach has the potential to achieve 15-20% weight savings compared to a conventionally produced component. It marks a milestone in lightweight design that meets the stringent quality requirements of Mercedes-Benz.

BIONICASTTM Damping Dome

BIONICAST is a registered trademark of Mercedes-Benz applied to structural castings designed according to the principles of nature. In addition to the BIONEQXX rear floor casting, another BIONICAST component featured on the VISION EQXX is the shock domes that accommodate the suspension components at the front of the car. Like the BIONEQXX casting, they also make a significant contribution to keeping weight to a minimum, saving around four kilograms compared to conventional pressed domes. The mount that carries the VISION EQXX’s windshield wipers and motor was also designed using bionic engineering principles. Here too,

This technology has already been transferred to Mercedes-Benz production models. For example, the chassis components of the new EQS have been modified to reduce weight while increasing stiffness.

Advanced body materials deliver advances in lightweight design, safety and sustainability

The VISION EQXX features a host of advanced materials that deliver practical functionality and safety to exacting Mercedes-Benz standards. Several of these materials are currently being used in the development of future production models.

The MS1500 ultra-high-strength martensitic steel used in the VISION EQXX marks a first for a Mercedes-Benz body-in-white application. The exceptional resistance of this material offers excellent protection to the occupants in the event of an impact, keeping the weight to a minimum.

The VISION EQXX body-in-white is one of the first Mercedes-Benz applications of low-CO2 flat steel produced from 100% scrap metal using an electric arc furnace technique. These low CO2 steel grades have only recently been introduced in Mercedes-Benz production vehicles and represent a blueprint for future models. In fact, the cooperation between Mercedes-Benz AG and Salzgitter Flachstahl GmbH won the MATERIALICA Design + Technology Gold-Award 2021[13] in the category “CO2-Efficiency”.

The doors of the VISION EQXX are made from hybrid components of CFRP and GFRP (glass and carbon fiber reinforced plastics) with aluminum reinforcements. In addition to the weight benefits, this design also strikes a careful balance of stiffness and ductility in the event of a crash. Meanwhile, a new polyamide foam reinforces the lower edge of the door and optimizes energy absorption in the event of a side impact.

Lightweight design thinking was applied throughout the VISION EQXX. On the chassis, aluminum brake discs significantly reduce mass compared to cast steel discs. As well as being completely corrosion-free, this brake system designed by Mercedes-Benz Advanced Engineering also reduces brake dust emissions by up to 90% thanks to an innovative coating. Meanwhile, new advanced fiberglass-reinforced plastic springs developed in partnership with Rheinmetall Automotive shed more weight compared to conventional coil springs.

Neuromorphic computing: a car that thinks like you

Another key efficiency feature of the VISION EQXX that follows nature’s lead is the way it thinks. It uses an innovative form of information processing called neuromorphic computing. The hardware runs so-called spiking neural networks. Information is encoded into discrete spikes and power is only consumed when a spike occurs, reducing power consumption by orders of magnitude.

Working with artificial intelligence experts at California BrainChip, Mercedes-Benz engineers developed systems based on BrainChip’s Akida hardware and software. The example in the VISION EQXX is the detection of hot words “Hey Mercedes”. Structured according to neuromorphic principles, it is five to ten times more efficient than conventional voice control.

Although neuromorphic computing is still in its infancy, systems like these will be commercially available in a few years. When applied at scale across a vehicle, they have the potential to radically reduce the energy required to run the latest AI technologies.

UI/UX in VISION EQXX: the non-judgmental travel companion

On a road trip, it’s nice to have someone with you. A road trip companion helps with navigation. They could be in charge of the music selection. Or maybe they’re clutching the travel guide, pointing out places of interest and fascinating tidbits of information along the way. They might even offer an occasional “tip” on driving style. However, it is true that this type of “help” can also be a source of friction. In the VISION EQXX, all this and more is taken care of by the car, allowing driver and passenger to relax and enjoy each other’s company.

The VISION EQXX shows us the potential of game engine driven interfaces, with graphics like never before seen and a highly responsive design. The user interface demonstrates how real-time graphics enable new digital worlds that instantly respond to the driver’s needs and bring the real world into the car.

The user interface and user experience within VISION EQXX catapults us into a highly responsive, intelligent, and software-driven future. Stunning to look at, intuitive to work with and attuned to the human mind, the first fully integrated display in a Mercedes-Benz spans 47.5 inches from A-pillar to A-pillar. With a resolution of 8K (7680 × 660 pixels), the thin and light mini-LED display acts as a portal that connects the driver and occupants to the car and the outside world. A star cloud avatar, reminiscent of our namesake Mercedes Jelinek, is the ethereal guide. Changing shape in response to the needs of the driver and taking care of the passengers, it turns the journey into a luxurious experience.

The Mercedes-Benz team worked with navigation experts NAVIS Automotive Systems, inc. (NAVIS-AMS) to develop the first real-time 3D navigation system on a screen of this size. It performs continuous zoom and scroll functions from the satellite view up to a height of 10 meters in the 3D city representation. Executed on the one-piece screen, it offers the user an astonishingly clear, precise and intuitive route guidance.

It’s also fun to talk to your fellow road tripper in the VISION EQXX. The further development of the “Hey Mercedes” voice assistant is emotional and expressive thanks to a collaboration between Mercedes-Benz engineers and Sonantic speech synthesis experts. With the help of machine learning, the team has given “Hey Mercedes” its own distinctive character and personality. As well as sounding breathtakingly real, the emotional expression takes the conversation between driver and car to a whole new level that is more natural and intuitive, underscoring the progressive feel of modern luxury conveyed by the UI/UX in the VISION EQXX.

Efficient use of energy and information

The one-piece screen is also very energy efficient. Its mini-LED backlight features more than 3,000 local dimming zones, meaning it draws power only when needed on specific parts of the screen.

The 3D navigation screen adapts to the type of content being displayed. For example, if you’re driving in an urban area, the abstract display of surrounding buildings helps you orient yourself in the midst of densely populated streets. However, if you are traveling on a motorway or open road, the level of detail decreases to provide a clearer overview of the journey. This has the added efficiency benefit of reducing the display’s power consumption.

As well as providing smooth navigation, the intelligence of the VISION EQXX can extract data based on the car’s route, with the avatar at hand to function as an intelligent tour guide. It can even help you manage your music library and offer local suggestions.

There is also a system to help you drive more efficiently. From power flow to terrain, battery status and even the direction and intensity of the wind and sun, the efficiency assistant selects all available information and suggests the most efficient driving style. This actually enhances the driver’s senses by providing information about external conditions that the driver himself cannot feel directly, in the same way that, for example, a cyclist can feel the force of the wind or the extra effort involved in pedaling uphill. . This sensory support is enhanced by the VISION EQXX’s ability to use map data to “see the future”, anticipating what lies ahead to help the driver take advantage of it in a way that maximizes efficiency.

And if you want more detailed information, a series of screens will tell you everything you need to know with easy-to-follow images and infographics. The influence of current acceleration, slope, wind and rolling resistance on energy consumption are displayed in real time. If it’s a complete analysis you want, it’s got it. Likewise, if you’re someone who prefers to travel on a “need to know” basis, the VISION EQXX will keep you schtum.

The simplicity of the interface is a further development of the Zero Layer concept first used in the EQS, which facilitates interaction between driver and vehicle by doing away with sub-menus. The interface is efficient and effective, thanks to intelligence and customization. Highly proactive, it shows you what you need when you need it, with an intuitive zoom function that provides access to all features. Your human road trip companion has its own zoom feature and entertainment zone. And if you prefer to travel alone, this part of the screen turns off to save energy.

Weaving sound into the equation

Finally, the VISION EQXX’s sound system is intertwined with the UI/UX to deliver a stunning 4D experience with exceptional power efficiency. A typical sound system can be a significant energy consumer, so Mercedes-Benz engineers took a close look at how to optimize the sound experience while minimizing energy consumption. This can be achieved by reducing the degradation that sound waves experience when they are absorbed by or bounced off interior surfaces.

Problem solved: Reducing the total number of speakers and placing them in close proximity to individual occupants dramatically reduces the distance sound travels. Two wideband speakers installed in each headrest are combined with a bass driver in each seat. The VISION EQXX uses the drivers for normal audio output as well as vehicle sounds, haptic feedback, and audio warning. The efficient combination of sound and haptic feedback is a highly efficient way to increase perception and awareness through the use of more stimuli.

In addition to reducing power consumption, the sound system design in the VISION EQXX also facilitates multiple different sound zones. Efficiency Assistant takes advantage of the sound system to communicate its recommendations to the driver through a series of intuitive audio ‘cues’. These were inspired by the signs used by Formula E racing to help drivers perform more efficiently.

The development and testing process: a software-driven digital journey

The global road trip to electric mobility is powered by advanced software and digital processes. The roads and byways are many and varied, the attractions and connections along the way inspiring.

Bringing together such a diverse array of experience and innovative ideas from around the world to create VISION EQXX in twice the time was a masterclass in software management. The team made extensive use of open source technology, augmented by elements created in-house. Agile working practices and monthly release planning ensured a seamless end-to-end feature flow and early solution integration.

The scale of the digital development work involved in the design and engineering of the VISION EQXX is truly groundbreaking. Highly advanced digital tools such as virtual and augmented reality have dispensed with the need for time-consuming physical mock-ups. It also facilitated the simultaneous development work of remote teams working in different parts of the world, from Stuttgart (Germany) to Bangalore (India) and from Brixworth (UK) to Sunnyvale (California). This massive improvement in digital power reduced the time spent in the wind tunnel from over 100 hours to just 46. It also meant that over 300,000 kilometers of test driving were covered virtually.

Digital development made extensive use of Software in the Loop (SiL) systems. This made the commissioning phases with the real hardware extremely short and allowed us to carry out large-scale tests early in the project. Using this approach, the team was able to install the drive unit, update the software and get the wheels rolling on the VISION EQXX in just two hours. This extremely agile, efficient and responsive teamwork was made possible by a combination of a sporty mentality and clever use of comprehensive testing options at Mercedes-Benz.

This highly effective and efficient digital development approach means that many of the innovations in the VISION EQXX could be quickly adapted for production applications.

DID YOU KNOW THAT THE VISION EQXX…

…achieve more with less

Being efficient is about reducing waste to the absolute minimum in order to make the most of what you have, be it energy, time or resources. In the Mercedes-Benz VISION EQXX, efficiency means more range with less energy, more tangible luxury and comfort with less impact on nature, and more electric mobility with less waste. It also means radically shorter development times through the application of advanced digital tools and cross-functional teamwork.

…can go from Berlin to Paris on a single charge

A single charge of the VISION EQXX would take you from Berlin to Paris, New York City to Cincinnati, Ohio, or Beijing to Nanjing. Not because it has a big battery, but because it is very efficient. Based on average distances driven per year, a driver in the US or China would need to fully recharge the VISION EQXX only twice a month and in Europe only once a month[14].

…it is the electrical equivalent of a “1 liter car”

The VISION EQXX uses less than 10 kWh of electrical energy to travel 100 km[15]. That is equivalent to traveling 6 miles on 1 kWh of electrical energy. But what does that mean? Translated into fossil fuel consumption, this is around the golden figure of 1 liter per 100 kilometers (235 mpg in the US or 282 mpg in the UK).

Here are some examples of what 10 kWh of energy offers in other areas of life:

- Run a dryer for just over 3 hours.

- Run an average home air conditioner for about 3 hours

- Use an iron for 5 hours.

- Watch a 50-inch LED TV for 100 hours

- Run conventional (non-LED) floodlights in a major sports stadium for about 3 minutes

…is more streamlined than a football

On a long-distance trip, a typical EV uses about two-thirds of its energy just making its way through the air. At 0.17[16], the VISION EQXX’s innovative cd figure can make a big difference at highway cruising speeds. A reduction of just 0.01 adds about 2.5% to the range. Let’s put it in context with some other drag coefficients:

- Penguin – 0.05

- EQXX VISION – 0.1716

- RCT – 0.20

- American football – 0.18 to 0.2

- Cyclist – 0.6 to >0.8

- Person – 0.8 to 1.2

- Parachute – 1.1 to 1.3

[1] Electricity consumption has been determined on the basis of Commission Regulation (EU) 2017/1151 according to WLTP

[2] Preliminary range figures and based on digital simulations under real traffic conditions. The VISION EQXX has not undergone type approval or homologation.

[3] Preliminary range figures and based on digital simulations under real traffic conditions. The VISION EQXX has not undergone type approval or homologation.

[4] Preliminary range figures and based on digital simulations under real traffic conditions. The VISION EQXX has not undergone type approval or homologation.

[5] cd figure measured in the Daimler aeroacoustic wind tunnel at a wind speed of 140 km/h

[6] Preliminary range figures and based on digital simulations under real traffic conditions. The VISION EQXX has not undergone type approval or homologation.

[7] cd figure measured in the Daimler aeroacoustic wind tunnel at a wind speed of 140 km/h

[8] cd figure measured in the Daimler aeroacoustic wind tunnel at a wind speed of 140 km/h

[9] On January 28, 1938, the record car Mercedes-Benz W 125 set the world speed record on public roads, which still stands today, with its cd value of 0.17: Rudolf Caracciola reached a speed of 432.7 km/h on the A5 motorway between Darmstadt and Frankfurt at the time.

[10] The record-breaking C111-III had a drag coefficient of 0.183

[11] First non-sports car from Mercedes-Benz to feature active aerodynamics for a drag coefficient of 0.19

[12] Automotive Sustainability Award 2021 | Roland Berger

[13] MATERIALICA Design + Technology Award 2021 | Salzgitter Flachstahl GmbH

[14] The average American drives 13,500 miles (21,600 km) a year. In Europe, that figure is around 12,000 km (7,500 mi) and in China 20,000 km (12,500 mi). https://www.fhwa.dot.gov/ohim/onh00/bar8.htm https://www.globalfueleconomy.org/transport/gfei/autotool/case_studies/apacific/china/cs_ap_china.asp https://www. odyssee-mure.eu/publications/efficiency-by-sector/transport/distance-travelled-by-car.html

[15] Preliminary range figures and based on digital simulations in real traffic conditions. The VISION EQXX has not undergone type approval or homologation.

[16] cd figure measured in the Daimler aeroacoustic wind tunnel at a wind speed of 140 km/h